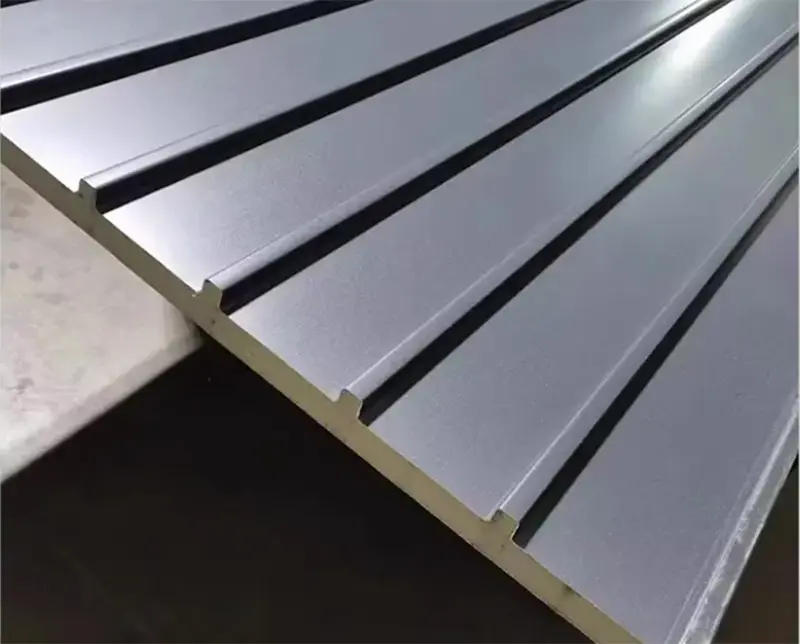

Metal Sheet Panel for roofing and wall,Galvalume steel Aluminum alloy material corrugated Construction Material

Specification

|

Prodcut Name |

Corrugated Aluminum alloy/ Steel sheet |

|

Core Material |

Al-1060 \ Al-3003 \Al-3004; Galvanized |

|

Width |

Expand Width 1000mm,Effective width800mm |

|

Lenth |

According to customer’s requirements,≤5.8m |

|

Thickness |

Aluminum thickness :0.6mm - 1.2mm; Steel Thickness : 0.32mm - 0.6mm |

|

Density |

Aluminum : 2.73g/cm3 ; Steel :7.85g/cm3 |

|

Color |

Usual color ---Grey; Accept custom |

|

Surface paint |

PE,SMP,HDP, PVDF |

|

Life span |

Fluorocarbon paint surface 50 years |

|

Application |

Building roofing and wall |

|

MOQ |

Special color 35t |

Product Description

This kind of roofing products can be different METAL MATERIAL,such as COLOR STEEL,GALVANIZED STEEL,GALVALUME STEEL, ALUMINUM MAGNESIUM MANGANESS MATERIALS and Other Aluminum alloy materials.

Therefore, the selection of metal material plates is relatively wide and the price range is relatively large, suitable for customers with different budget needs and functional needs. Customers can combine the advantages and disadvantages of different materials to choose the product that suits them.

Compared to non-metallic roofing products, it has significant disadvantages

1. Poor sound insulation effect

- Metal materials transmit sound obviously, and the noise is loud when raindrops and hail hit, so additional sound insulation layer or insulation material needs to be laid.

2. Insufficient thermal insulation

- Metal has high thermal conductivity, absorbs heat quickly in summer and dissipates heat quickly in winter, and needs to be used with an insulation layer (such as rock wool, polyurethane foam), which increases costs.

3. Thermal expansion and contraction problems

- Temperature changes can easily cause metal tiles to deform or loosen at the joints, so expansion joints need to be reserved and the sealing needs to be checked regularly.

4. Aesthetic limitations

- It has a strong industrial feel and may not be in harmony with traditional architectural styles (such as Chinese and European roofs).

5. Surface coating damage and easy to rust

- If the surface coating is scratched or corroded (such as coastal high-salt environments), the metal substrate is prone to rust and requires regular maintenance.

6. Inconvenient maintenance and replacement

- After damage, tiles of the same specification need to be replaced. If production is discontinued or the batches are different, there may be color differences or matching difficulties.

Advantages

1. It has good wind resistance and earthquake resistance and can withstand extreme weather (such as typhoons and hail).

2. Light weight, reducing the load of the building structure and reducing the cost of the support frame. The transportation cost is relatively low.

3. The corrugated design can quickly divert rainwater and reduce the risk of water accumulation; the joints are overlapped to ensure reliable waterproofing effect.

4. The metal material is non-combustible (A-level fireproof), suitable for places with strict fire protection requirements.

5. Easy to install, fast construction speed, suitable for large-area paving.

6. Metal materials can be 100% recycled and reused, in line with the concept of green buildingshy choose us

Project case

Packing and shipping