Global popular Classical Bond Harvey Colored Stone Coated Galvanized Zinc Steel Metal Roofing Sheet

Specification

|

Prodcut Name |

Color stone coated metal tile |

|

Core Material |

Aluminum- zinc steel sheet+Colored sand+Acrylic resin |

|

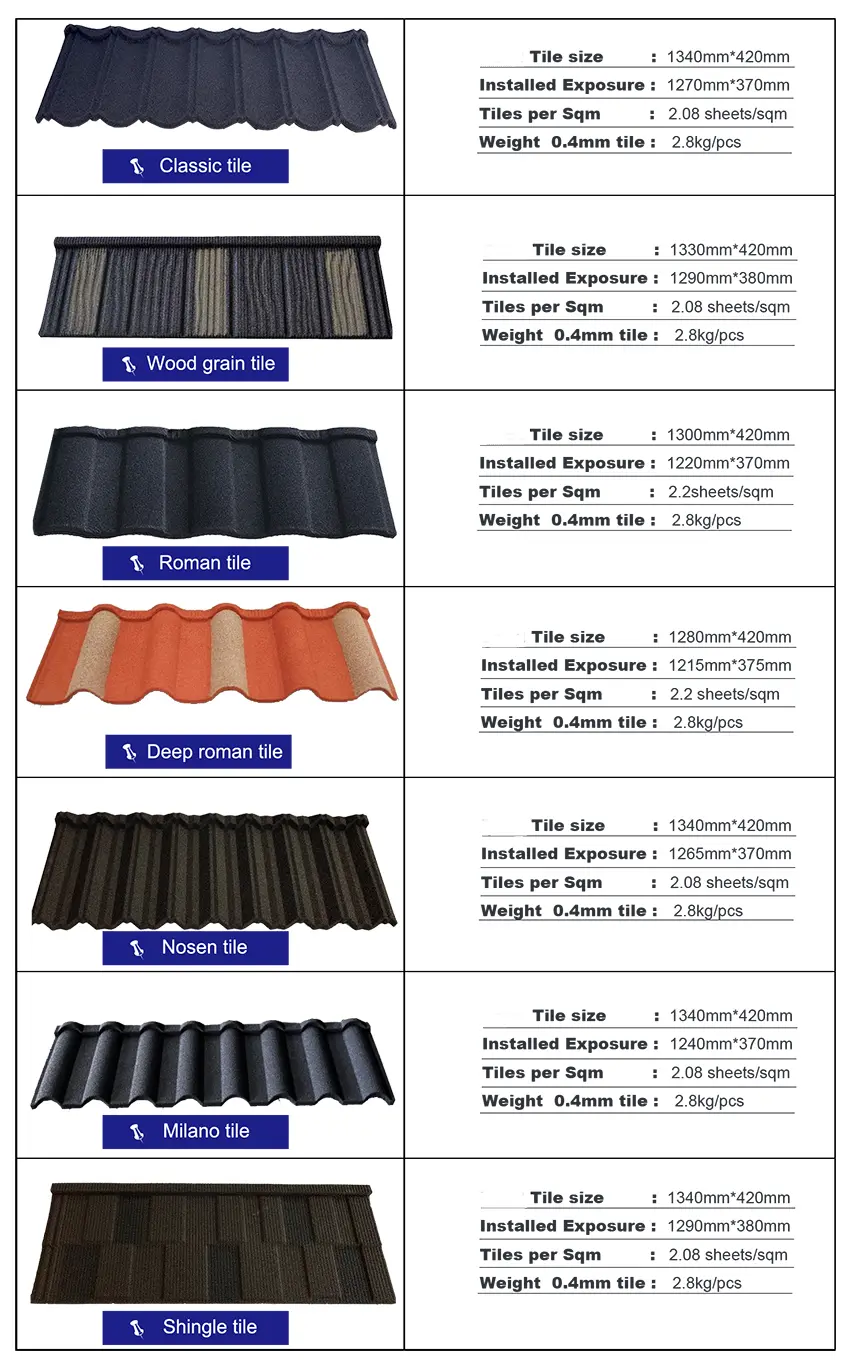

Style |

Bond \ Classic \ Milan \ Roman \Deep roman \Wood grain \Shingle \ |

|

Size |

1340mm*420mm ; 2.1sheets / sqm |

|

Weight |

1.9kg / pc - 3.9kg / pc |

|

Thickness |

0.20mm \ 0.28mm \0.35mm \0.40mm \0.45mm \0.5mm |

|

Color |

Accept custom ,Black,Grey, Red, Orange, Blue |

|

Service |

Total solution for project \ online technical support |

|

Package |

600pcs / pallet |

|

Life span |

40 - 50 years |

|

Application |

Villas, bungalows, community buildings and so on |

Product Description

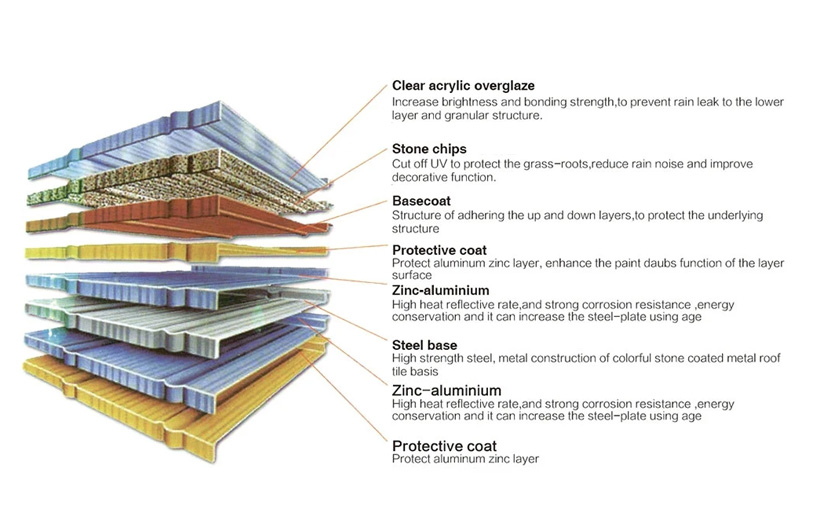

It is made of colored sand, acrylic resin, acrylic ester, fingerprint-resistant coating, and galvanized steel plate as the base material.

6% silicon, 43.4% zinc, and 55% aluminum make up the hot dip solution used to hot dip medium-galvanized steel sheets. It can be processed similarly to galvanized steel sheets and has similar coating qualities. Typically, it lasts two to six times longer than regular galvanized sheets.

The aluminum-zinc coating has a coating that resists fingerprints. The aluminum-zinc layer is shielded in part by the coating that resists fingerprints. In addition, a stronger bond between the colored sand and the aluminum-zinc steel plate can be achieved by the fingerprint-resistant coating. The coating that resists fingerprints Three categories exist for the color: light green, transparent, and colorless.

The base protective layer and decorative layer of the metal tiles are made of sintered colored sand. It is created using high-temperature sintering and sophisticated coloring techniques to create basalt particles of a specific size. It can lessen the noise made by rain on metal tiles, comes in more than ten colors, and is UV resistant.

The essential ingredient for joining colored sand and steel plates is acrylic. It also acts as a barrier on the sand's surface to keep tiny drops of rainwater from leaking through and prolong the sand's color.

Note: NOTE: Due to the influence of factors such as shooting settings, monitors, lighting,angles, etc., there will be color differences between the pictures you see and the actual objects.

Classification

Advantages

DISAdvantages

Higher price: Production needs to consider the cost of steel and special production processes. Compared with ordinary tiles, the price is a little more expensive, which will increase construction costs.

Difficult to distinguish quality: The market competition is fierce. In order to reduce costs, some manufacturers will use inferior raw materials, such as thin galvanized steel sheets, inferior glue, dyed sand, etc. These problems are difficult to distinguish with the naked eye.So it's vital that purchase the items through a professional supplier.

Susceptible to environmental influences: Under extreme climatic conditions such as strong winds, heavy rain, and heavy snow, the edges and corners of checkered colored stone metal tiles are more likely to deform or fall off due to uneven stress than some other tile types.

Inconvenient cleaning and maintenance: The checkered type has many grooves and gaps, which can easily accumulate dust, leaves and other debris, making it relatively difficult to clean. Long-term accumulation of water or debris may cause corrosion or damage.

High installation requirements: The installation of checkered colored stone metal tiles requires more precise operations to ensure that the splicing between squares is tight and neat. Otherwise, the appearance and waterproof performance will be affected, and the technical level of the construction personnel is required to be high.

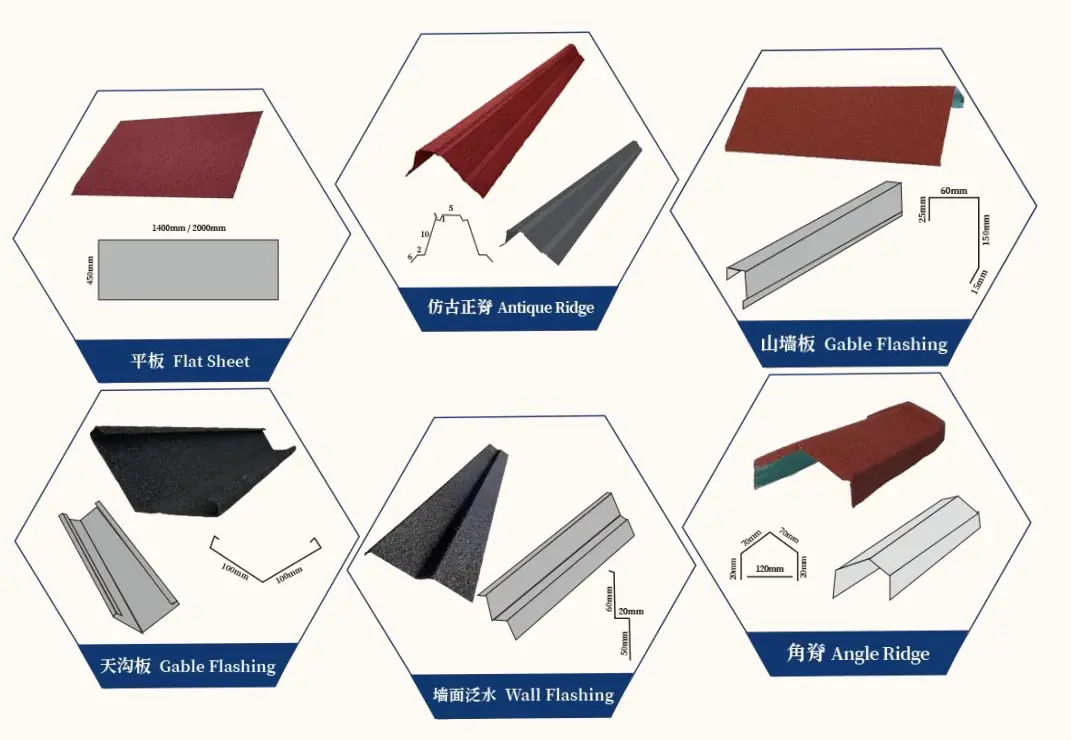

Accessories

NOTICE IN INSTALLING

distinguish quality

To know the product quality, we can also judge product quality through some simple methods in addition to inspection reports, Details as follow.

1. Material anti-corrosion performance, mainly the quality of galvanized steel plate.Because it is the essential factor of affecting the service life of the tiles.

look at the spangles on the back, the stronger the three-dimensional effect, it proves that the proportion of galvanized aluminum is high. At the same time, some acid and alkali substances can be used to test the corrosion resistance of steel plates.

2. The bonding degree of colored sand, which is the core process of this product.

Scrape a gap on the surface with a scraper to remove the primer completely. Push the screwdriver and the tile at an angle of 30 degrees. The more colored sand and glue removed, the worse the quality will be. The debris is normal.

3. The cleanliness of the surface colored sand.Qualified colored stone metal tiles will not have the phenomenon of surface sand exposed, local accumulation, and different shades of color.

PERFORMANCE GUARANTEE

The Guangshengjia brand colored stone metal tiles are produced using the latest generation of automated production equipment, with strict material selection and exquisite workmanship. We have passed ISO 9001 certification and have quality test reports, evaluations and field results, which prove that our products are 100% waterproof, earthquake-resistant, fireproof and can withstand hurricanes up to 190kph. When you buy a product, you also buy trust. Your trust is our motivation, and we will do our best to protect your investment of trust and financial resources.

Note: Due to the different skills of the construction team, we cannot guarantee the final installation effect.

Project case