Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

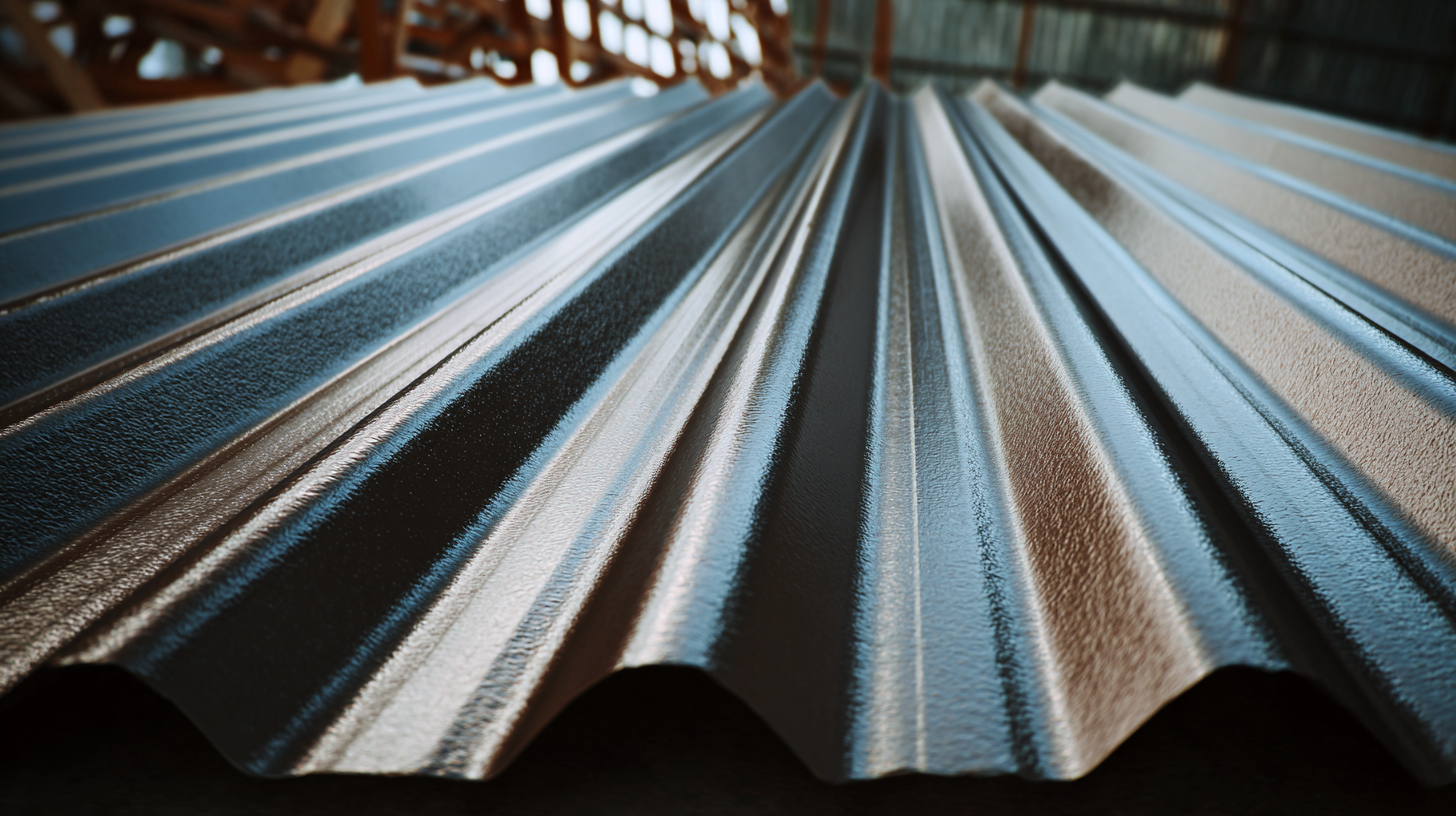

In the rapidly evolving landscape of global trade, the demand for high-quality materials plays a crucial role in ensuring structural integrity and sustainability. Among these, the Sheet Roof stands out as a vital component in construction, offering durability and protection against the elements. However, with countless manufacturers vying for attention, selecting the right producer becomes paramount.

This blog aims to guide you through the process of choosing a superior Sheet Roof manufacturer. We will explore key factors such as material quality, production standards, and customer service, equipping you with the knowledge needed to make an informed decision.

By the end, you will not only understand how to identify unmatched quality in Sheet Roof manufacturing but also how this choice can significantly impact your construction projects and the broader framework of international trade, particularly from the renowned manufacturing hub of China.

In the ever-evolving world of construction materials, the standards of excellence in sheet roof manufacturing play a pivotal role in transforming global trade dynamics, particularly from China. According to a recent report by MarketsandMarkets, the global roofing materials market is projected to grow from USD 101.5 billion in 2022 to USD 125.3 billion by 2027, showcasing the increasing demand for high-quality roofing solutions. Chinese manufacturers have been at the forefront of this transformation, driven by their commitment to innovative practices and stringent quality controls, which are essential in meeting international standards.

When it comes to sheet roof manufacturing, adhering to specifications such as ASTM and ISO standards is vital. These guidelines not only ensure the durability and longevity of roofing products but also contribute to sustainable practices, which the industry is increasingly prioritizing. Tip: Invest in manufacturers that can showcase their certifications and past performance data, as this is a strong indicator of reliability and workmanship quality.

Furthermore, advancements in materials technology have introduced products that are both lightweight and robust, which is crucial in high-wind regions. A report by Technavio highlights that the metal roofing segment alone is expected to grow at a CAGR of over 5% during 2023-2027, driven by heightened awareness of energy efficiency and environmental impact. Tip: Always choose roofing materials that offer superior thermal performance, as this can significantly reduce energy costs and enhance overall building efficiency.

Chinese innovation has revolutionized the global sheet roof supply chains, making China a powerhouse in this sector. The infusion of cutting-edge technology and smart manufacturing practices has significantly enhanced the efficiency and quality of production processes. For instance, the adoption of automated systems and AI-driven analytics enables manufacturers to optimize production lines, reduce waste, and ensure unparalleled quality control. These advancements not only lower operational costs but also enable rapid response to market demands, thereby solidifying China's position as a go-to supplier for high-quality sheet roofing materials.

Furthermore, China’s commitment to research and development in building materials has led to the creation of innovative products that cater to diverse climatic conditions and architectural styles. The introduction of energy-efficient and eco-friendly roofing solutions showcases the country's dedication to sustainability and environmental responsibility. This relentless pursuit of innovation not only bolsters local manufacturing capabilities but also strengthens international trade ties as countries around the world look to China for reliable, high-performance sheet roofing options, transforming the landscape of global trade.

In the competitive landscape of roof sheet manufacturing, China has emerged as a formidable player, setting unmatched standards in quality. When comparing Chinese manufacturers to their global counterparts, it becomes evident that innovations in production processes, stringent quality control measures, and extensive research and development have positioned China at the forefront of the industry. The utilization of advanced materials and technology contributes significantly to the durability and performance of roofing sheets produced in China, making them a preferred choice for many international markets.

However, global competitors are not to be underestimated. Countries such as Germany, the United States, and South Korea are enhancing their manufacturing capabilities to meet the evolving demands of consumers. They emphasize sustainable practices and the use of eco-friendly materials to create roof sheets that not only compete in quality but also in environmental consciousness. As these nations invest in cutting-edge technology and adapt to market trends, the gap between China's roof sheet manufacturing excellence and that of its global rivals is narrowing, pushing the industry toward a more diverse and competitive future.

| Country | Average Thickness (mm) | Tensile Strength (MPa) | Corrosion Resistance (Years) | Warranty Period (Years) | Market Share (%) |

|---|---|---|---|---|---|

| China | 0.5 | 450 | 15 | 20 | 50 |

| USA | 0.6 | 480 | 20 | 25 | 25 |

| Germany | 0.55 | 425 | 18 | 22 | 15 |

| Japan | 0.5 | 460 | 17 | 20 | 10 |

| South Korea | 0.55 | 440 | 16 | 18 | 12 |

Sustainability is at the forefront of modern manufacturing, and the sheet roof industry in China exemplifies this commitment. As global demand for eco-friendly materials rises, Chinese manufacturers are actively adopting innovative practices to minimize their environmental impact. This includes utilizing recycled raw materials, implementing energy-efficient production processes, and adhering to strict waste management protocols. By integrating these sustainability measures, manufacturers not only enhance their credibility but also cater to the growing conscience of consumers who prioritize environmentally responsible products.

Moreover, the shift towards sustainable practices in sheet roof manufacturing is bolstered by governmental policies and incentives aimed at promoting green technologies. Many companies are investing in research and development to create sustainable alternatives that meet international standards. This focus on sustainability not only helps in reducing carbon footprints but also positions China as a leader in the global market for eco-friendly building materials. As a result, China is transforming the landscape of sheet roof manufacturing, demonstrating that sustainability and quality can coexist harmoniously.

As we look to the future of sheet roof production, the steel industry is poised for transformative changes that will impact global trade dynamics, particularly from major manufacturing hubs like China. With projections indicating a recovery and growth in the steel market over the next decade, manufacturers are expected to leverage advances in technology to enhance production efficiency and sustainability. Reports suggest that innovative practices, such as the adoption of smart manufacturing and eco-friendly processes, are likely to boost yield and improve the overall quality of sheet roofs.

Furthermore, as solar energy continues to gain traction, the integration of solar photovoltaic (PV) technology into sheet roofs is anticipated to rise significantly. According to industry forecasts, the solar PV market is expected to grow at a compound annual growth rate (CAGR) of over 20% in the next five years. This trend presents opportunities for sheet roof manufacturers to not only expand their product offerings but also align with global sustainability goals, thereby positioning themselves as leaders in the green energy sector. The focus on renewable energy will therefore play a crucial role in shaping the future of sheet roof production in China and beyond.