Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

A Roof Tile Factory plays a crucial role in the construction and building materials industry, providing essential products that ensure the durability and aesthetic appeal of roofing structures. According to the Global Roof Tiles Market Report, the industry is projected to grow at a CAGR of 4.2% from 2021 to 2028, driven by increasing urbanization and the rising demand for sustainable building materials. Efficient operations within a Roof Tile Factory are key to meeting this demand while minimizing waste and maximizing productivity.

Industry expert Dr. Emily T. Waters, a leading researcher in roofing materials, emphasizes the importance of operational efficiency in this sector, stating, "The future of Roof Tile Factories lies in adopting advanced manufacturing technologies and sustainable practices to meet the evolving needs of the construction industry." This highlights the necessity for factories to innovate and enhance their processes not only to reduce production costs but also to comply with environmental regulations. As the market continues to expand, mastering efficiency in operational procedures will be imperative for Roof Tile Factories striving to remain competitive and sustainable.

A roof tile factory is a specialized facility dedicated to the production of various types of roof tiles, which are critical for building construction and renovation. This factory typically operates with advanced technology to ensure precision in design and efficiency in output. According to a report by the Global Market Insights, the ceramic roof tile market alone is expected to achieve a compound annual growth rate (CAGR) of 5.1% from 2021 to 2027, driven by rising residential construction activities and the growing trend of sustainable building.

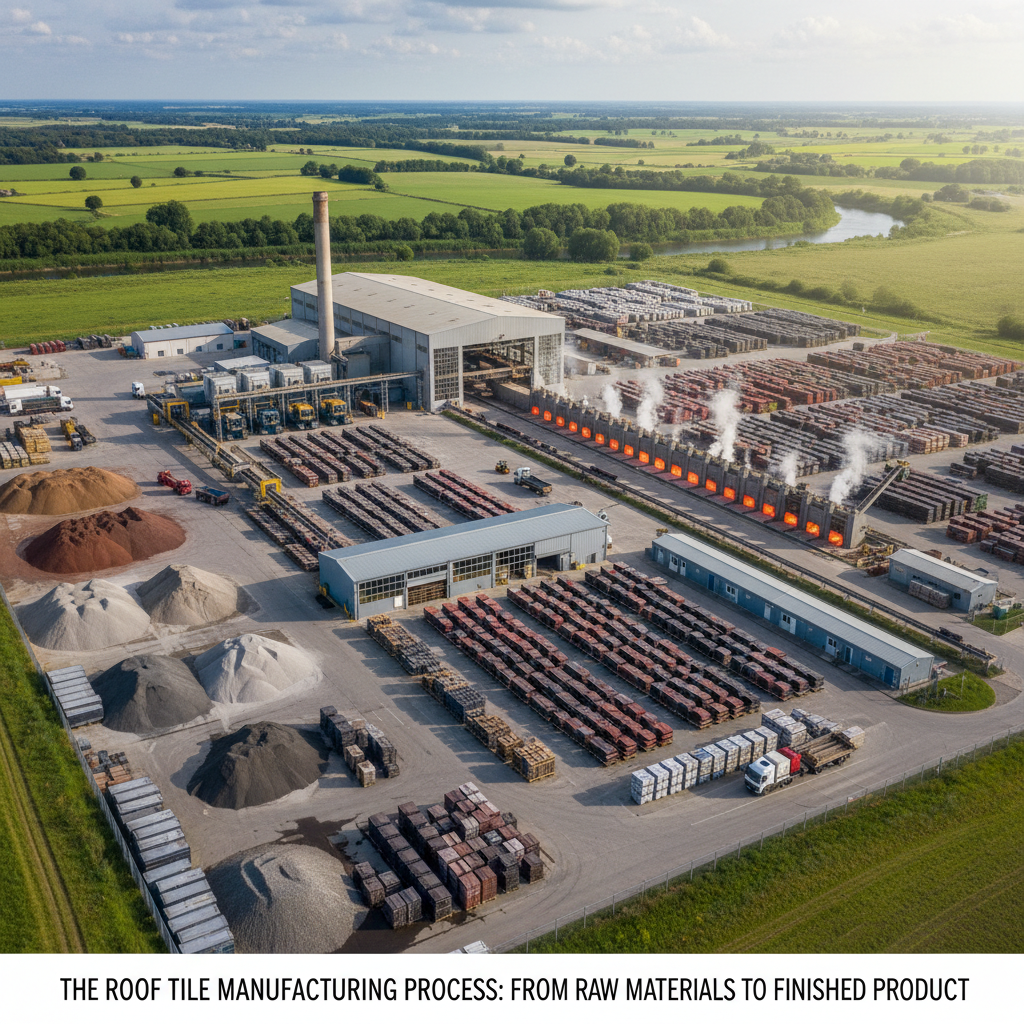

In a typical roof tile factory, raw materials such as clay, concrete, or slate are sourced and processed through a series of steps that include molding, drying, and firing. Modern factories utilize automated machinery that enhances production speed and minimizes waste, aligning with best practices noted in a 2022 industry analysis by Technavio that highlighted operational efficiencies achieved through automation could reduce costs by up to 20%. Efficient resource management, quality control, and adherence to environmental standards further contribute to a roof tile factory's ability to produce high-quality products while meeting market demands.

Roof tiles are essential components that provide protection and aesthetics to buildings, and their manufacturing process begins with selecting the right materials. The most commonly used materials in roof tile production include clay, concrete, and occasionally slate. Clay tiles are known for their durability and thermal resistance, making them a favored choice in various climates. Concrete tiles, on the other hand, offer versatility in design and color while being more cost-effective. Slate, renowned for its natural beauty and longevity, is often used in high-end constructions.

When operating a roof tile factory, it's crucial to optimize material handling and processing techniques. Efficient machinery can significantly reduce waste and improve production rates. For instance, automation in shaping and firing processes not only enhances consistency but also minimizes labor costs.

Tip: Always source materials from reputable suppliers to ensure quality and reduce defects in the final product. Consistent inspections and testing should be part of the process to maintain standards. Additionally, investing in training for your staff will improve operational efficiency and foster a culture of quality within the factory.

The roof tile manufacturing process is a complex operation that involves several key steps to ensure efficiency and quality. Initially, raw materials such as clay, concrete, or slate are sourced and prepared. For instance, according to a recent industry report by IBISWorld, the global roof tile manufacturing market is projected to grow at an annual rate of 3.5% over the next five years, reflecting the increasing demand for durable roofing solutions. After preparation, the materials undergo forming, where they are molded into various tile shapes, followed by drying and firing in kilns, ensuring they achieve the desired strength and durability.

To enhance operational efficiency, many factories employ techniques like lean manufacturing and automation. Using automated machinery reduces labor costs and minimizes errors, while lean methodologies focus on waste reduction. A study from the National Roofing Contractors Association emphasizes that factories adopting these techniques report up to a 25% increase in productivity.

Tips: When selecting a roof tile factory, consider their production capacity and technology used—these factors significantly impact lead times and overall quality. Additionally, always inquire about their sustainability practices, as an eco-friendly approach not only benefits the environment but can also foster a strong brand reputation in a competitive market.

Roof tile factories are increasingly leveraging advanced technologies to enhance operational efficiency and productivity. One prominent technology is automation, which streamlines the manufacturing process by reducing labor costs and minimizing human errors. Automated machinery can handle everything from mixing raw materials to shaping and curing tiles, resulting in a faster production cycle and consistent product quality. Additionally, implementing robotics for packaging and palletizing has significantly reduced manual labor, allowing workers to focus on quality control and maintenance.

Another key technological advancement is the use of data analytics and the Internet of Things (IoT). These systems enable real-time monitoring of production lines, helping managers detect inefficiencies or equipment malfunctions promptly. Predictive maintenance can be employed to anticipate machine failures before they occur, further reducing downtime and enhancing overall operational reliability. The integration of such technologies not only elevates production efficiency but also contributes to sustainability by optimizing resource usage and minimizing waste throughout the manufacturing process.

| Dimension | Details |

|---|---|

| Factory Size | 25,000 sq ft |

| Annual Production Capacity | 1 million tiles |

| Average Production Time per Tile | 2 hours |

| Number of Employees | 50 |

| Key Technology Used | Automated Pressing Machines |

| Energy Efficiency Rating | A+ |

| Waste Reduction Techniques | Recycling of Scrap Materials |

| Average Tile Lifespan | 50 years |

Quality control is a crucial aspect of roof tile production, ensuring that each tile meets industry standards and customer expectations. In a roof tile factory, various measures are taken throughout the manufacturing process to maintain high quality. This includes regular inspections of raw materials, monitoring the production environment, and conducting tests on the finished products. Each stage requires adherence to strict guidelines to minimize defects and ensure durability.

Tips for implementing effective quality control include establishing a comprehensive checklist for each production stage. This ensures that all necessary quality parameters are evaluated consistently. Additionally, investing in employee training can greatly enhance awareness of quality standards, empowering workers to identify and rectify potential issues promptly before they impact production.

Another important aspect is the use of advanced technology for quality assurance. Implementing automated systems to track production metrics and quality data can help in timely decision-making. Regular audits and feedback loops also play a vital role in refining processes and enhancing overall efficiency in roof tile production. By prioritizing these quality control measures, a roof tile factory can operate seamlessly and produce superior products that stand the test of time.