Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving landscape of the modern construction industry, the significance of a Roof Sheet Factory cannot be overstated. As per the Global Roofing Market report by Grand View Research, the roofing market is projected to reach USD 233.1 billion by 2027, with a substantial portion attributed to the increasing demand for durable and efficient roofing solutions. Roof sheet factories play a critical role in this sector, producing a variety of materials that cater to both residential and commercial projects. With advancements in technology and the growing emphasis on sustainable building practices, these factories are not only enhancing the quality and efficiency of roofing products but also contributing to the overall sustainability goals of the construction industry. This blog delves into the multifaceted contributions of Roof Sheet Factories, highlighting their importance in meeting the demands of contemporary construction while addressing environmental concerns.

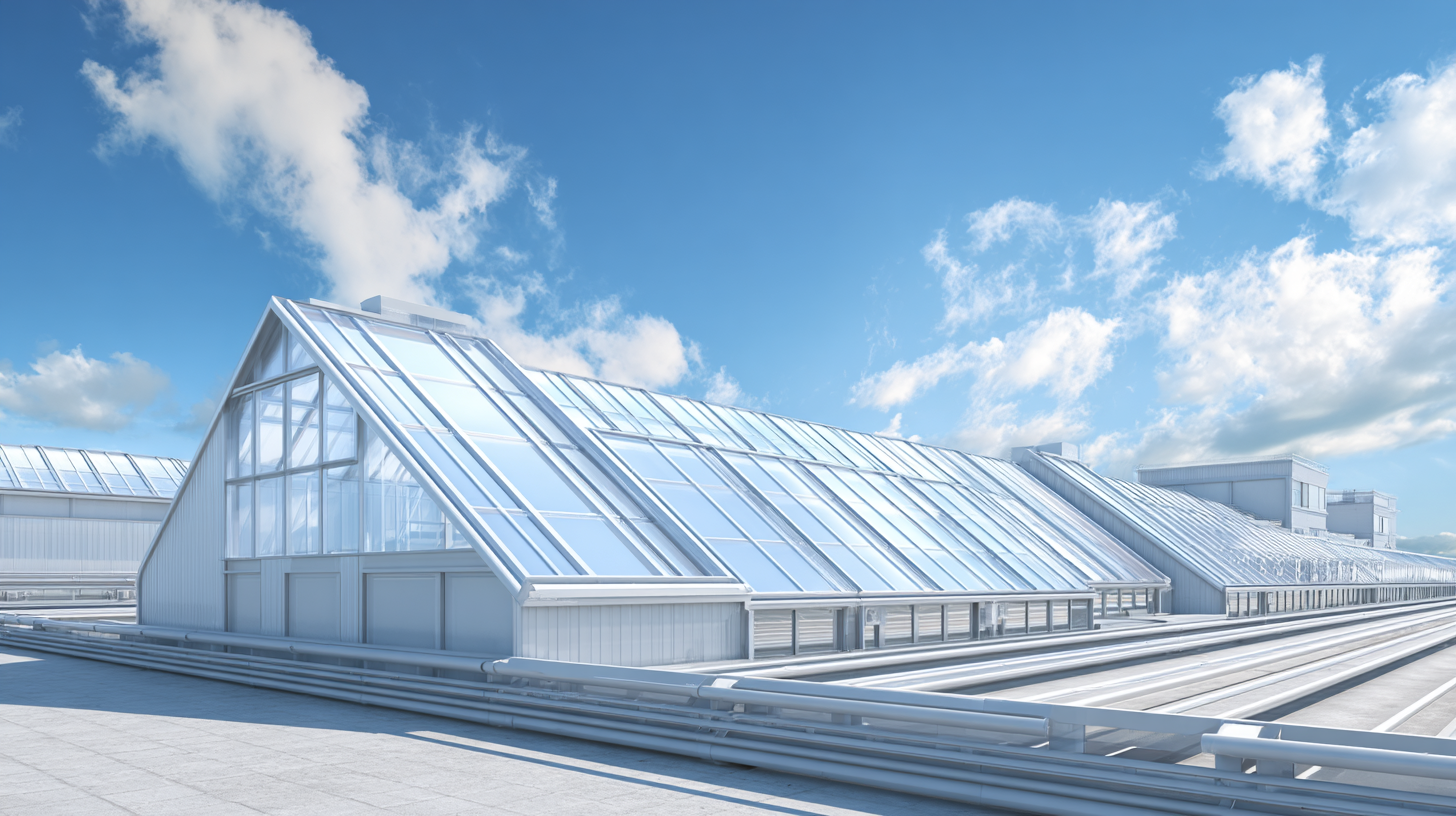

Roof sheeting plays a crucial role in the construction industry, providing essential protection and structural integrity to buildings. In modern construction, the materials used for roof sheeting—such as metal, polycarbonate, and asphalt—are not only designed for durability but also for energy efficiency. These materials help in regulating indoor temperatures, reducing the energy consumption associated with heating and cooling systems. This emphasis on energy efficiency aligns with global trends toward sustainable building practices, making roof sheeting a cornerstone of environmentally conscious construction.

Moreover, the aesthetic appeal of roof sheeting cannot be overlooked. With advancements in manufacturing techniques, roof sheets are available in various colors, textures, and styles, allowing architects and builders to enhance a building’s aesthetic value while maintaining functionality. The versatility of roof sheeting materials contributes to innovative designs and unique architectural features, enabling structures to stand out while meeting the practical needs of weather resistance and longevity. As the construction industry continues to evolve, the importance of roof sheeting remains at the forefront, underscoring its role as both a protective barrier and a design element in modern architecture.

This bar chart illustrates the different types of roof sheeting materials used in modern construction projects and their respective market shares. Roof sheeting is crucial in providing durability, insulation, and aesthetic appeal to buildings.

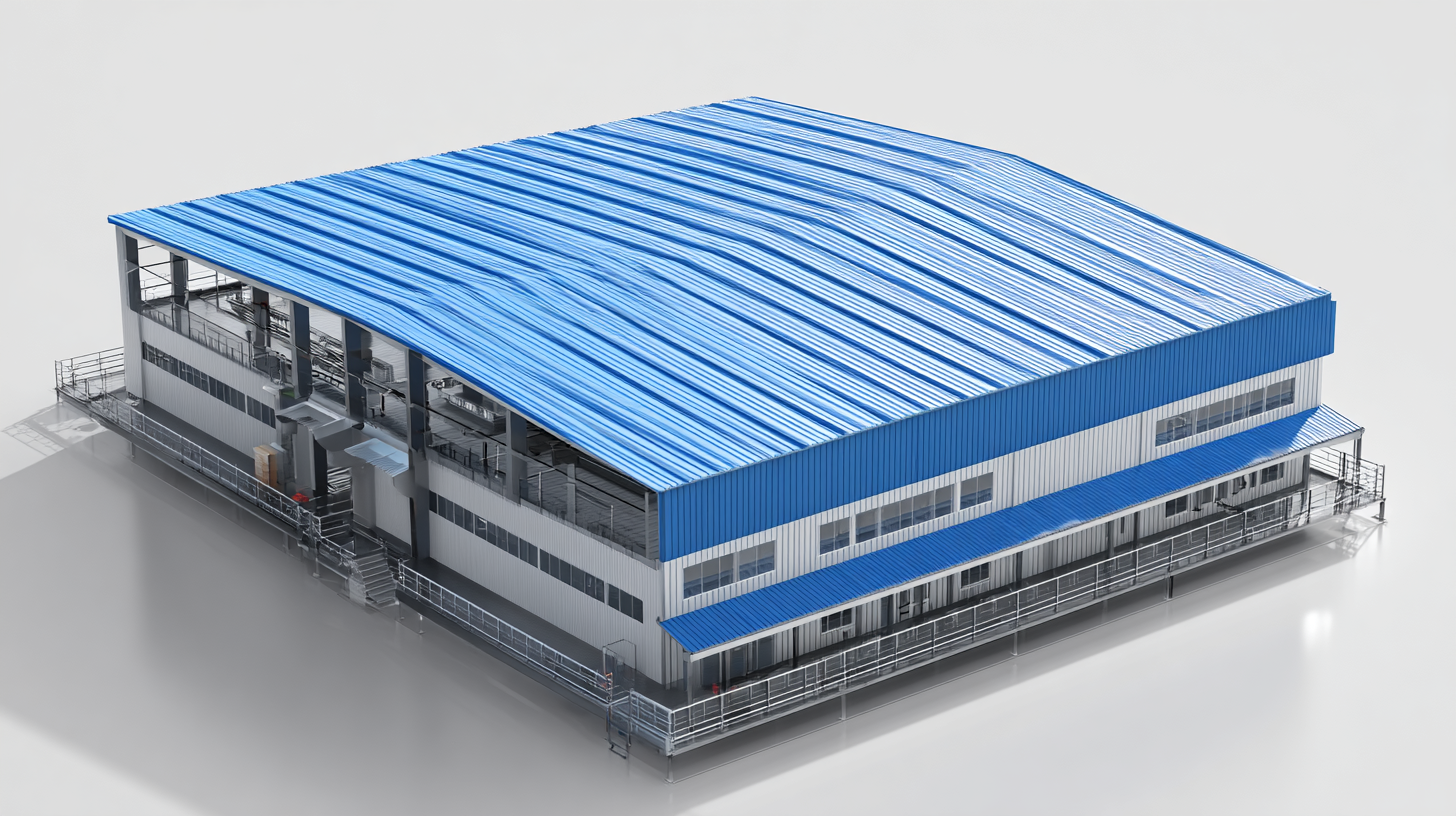

The manufacturing of roof sheets plays a crucial role in the modern construction industry, as it ensures the availability of durable and reliable materials necessary for various building projects. The process begins with the selection of high-quality raw materials, often metals like steel or aluminum, which are chosen for their strength and longevity. These materials undergo a series of treatments to enhance their corrosion resistance, a vital attribute considering their exposure to weather elements.

Once the materials are prepared, the next critical stage is the forming process. This involves using specialized machinery to shape the raw materials into the desired profile for roof sheets. Various profiles, such as corrugated, standing seam, or flat sheets, can be produced, depending on the project requirements. After forming, the sheets are cut to precise lengths and prepared for surface finishing, which can include painting or coating to improve aesthetic appeal and longevity. This comprehensive approach to roof sheet manufacturing not only ensures structural integrity but also contributes to energy efficiency and design flexibility in modern construction.

When it comes to modern construction, selecting the right materials for roof sheets is crucial for ensuring durability, energy efficiency, and aesthetic appeal. According to a report by the Global Roofing Materials Market, the sector is projected to reach a value of $138 billion by 2027, which underscores the growing importance of quality materials in roofing. The choice of roof sheets can significantly impact a building’s overall performance, with factors such as climate conditions and building design taking precedence in the selection process.

The first step in choosing the right materials involves understanding the various types of roof sheets available in the market. Materials like metal, PVC, and asphalt shingles each offer unique benefits depending on their application. For instance, a study published in the International Journal of Construction Management highlights that metal roofing can reduce energy costs by up to 30% due to its reflective properties. Furthermore, durability is essential; opting for high-performance materials can extend a roof's lifespan to 50 years or more, especially in harsh weather conditions. By carefully evaluating these materials and their properties, builders can ensure that their projects meet both functional and aesthetic standards, contributing to a sustainable construction future.

| Material Type | Durability | Weight | Cost per Sq Ft | Installation Difficulty |

|---|---|---|---|---|

| Steel | High | Moderate | $2.50 | Moderate |

| Aluminum | High | Light | $3.00 | Easy |

| Copper | Very High | Light | $8.00 | High |

| Zinc | High | Moderate | $5.00 | Moderate |

| Fiberglass | Moderate | Light | $1.80 | Easy |

Innovative technologies are reshaping the roof sheet production landscape in the modern construction industry. Advanced manufacturing methods, such as robotic automation and artificial intelligence, have significantly increased efficiency and precision. According to a recent report by the Global Industry Analysts, the roof sheet market is projected to reach $30 billion by 2026, driven by these technological advancements and an increasing demand for sustainable building practices. Automated systems are now capable of producing high-quality roof sheets at unprecedented speeds, reducing waste and labor costs.

Innovative technologies are reshaping the roof sheet production landscape in the modern construction industry. Advanced manufacturing methods, such as robotic automation and artificial intelligence, have significantly increased efficiency and precision. According to a recent report by the Global Industry Analysts, the roof sheet market is projected to reach $30 billion by 2026, driven by these technological advancements and an increasing demand for sustainable building practices. Automated systems are now capable of producing high-quality roof sheets at unprecedented speeds, reducing waste and labor costs.

A key area of innovation is the introduction of high-performance materials that enhance durability and energy efficiency. For instance, eco-friendly materials like recycled plastics and metal composites are paving the way for a greener construction approach. The U.S. Department of Energy estimates that roofs constructed with reflective materials can reduce cooling energy costs by up to 20%.

Tip: When selecting roof sheets, consider materials with high energy efficiency ratings to not only reduce costs but also contribute to environmental sustainability.

Furthermore, the integration of IoT (Internet of Things) technology in roof sheet factories allows for real-time monitoring and maintenance of manufacturing equipment, leading to decreased downtime and improved production quality. The shifting trend towards smart manufacturing is set to revolutionize how factories operate, positioning them as critical players in the construction industry's evolution.

Tip: Stay updated on the latest innovations in roofing technology to make informed decisions for your construction projects, as this can significantly impact long-term performance and sustainability.

Sustainability has become a crucial aspect of the modern construction industry, and roof sheet factories are playing a significant role in this shift. By adopting eco-friendly manufacturing processes, these factories minimize waste and reduce their carbon footprint. For example, many factories now utilize recycled materials in their production, which not only conserves resources but also lowers energy consumption during the manufacturing process. This commitment to recycling plays a substantial part in creating a circular economy within the construction sector.

Moreover, roof sheet factories are incorporating sustainable energy solutions, such as solar power, to run their operations. By harnessing renewable energy, they not only reduce reliance on fossil fuels but also demonstrate their commitment to environmental responsibility. Additionally, the use of modern technologies, like automation and precision engineering, allows these factories to optimize resource use and minimize production waste. As a result, consumers are increasingly drawn to eco-friendly options, leading to a rise in demand for sustainable construction materials that align with their values. This shift not only contributes to the welfare of the planet but also paves the way for innovative construction practices that prioritize environmental stewardship.