Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

A roof sheet is an essential component in modern construction. It serves as a protective barrier against the elements. These sheets come in various materials, including metal, plastic, and fiberglass. Each type has its unique advantages, such as durability and insulation.

Understanding how a roof sheet works can help in making informed choices. They are designed to direct water away, ensuring a dry interior. However, not all roof sheets perform equally well. Some may fade or crack over time. This can lead to leaks or costly repairs.

Choosing the right roof sheet requires attention. Homeowners must consider their local climate and budget. A wrong choice may result in unnecessary expenditures. A roof sheet should endure time and weather conditions, but not all options last. Reflecting on these decisions is crucial for long-term satisfaction.

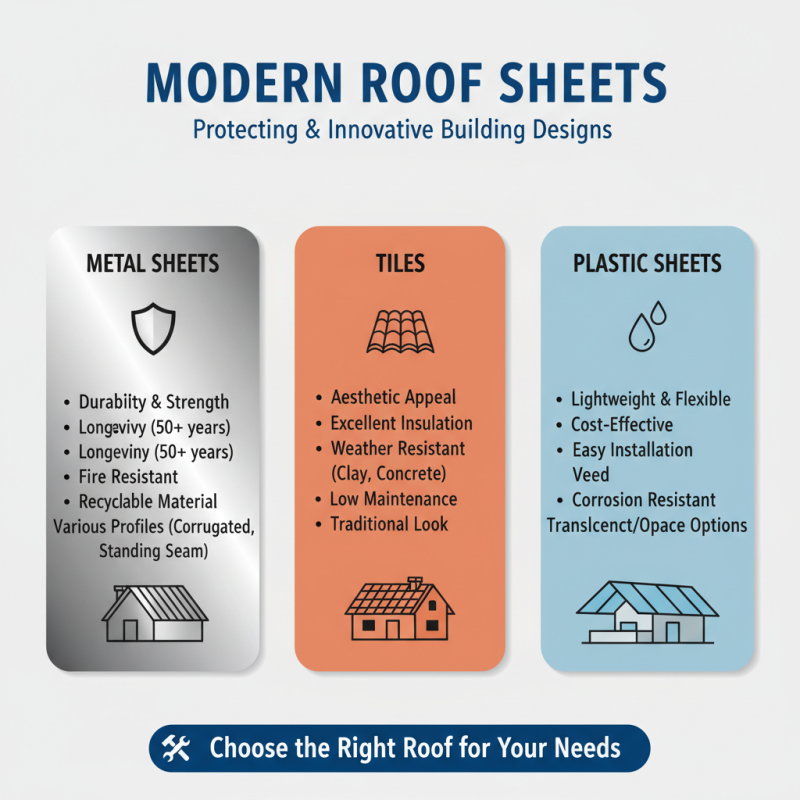

Roof sheets are crucial components of modern building designs. They serve as protective coverings, safeguarding structures from various weather conditions. Roof sheets come in different materials, including metal, tiles, and plastic. Each material has unique advantages. For instance, metal sheets provide durability, while plastic sheets are lightweight and cheaper.

According to industry reports, approximately 70% of new commercial buildings in the United States utilize metal roofing systems. These systems can last over 50 years with proper maintenance. However, some installations show signs of rust or wear due to poor quality materials or incorrect installation methods. It's important for builders to prioritize quality and consider the specific needs of the structure when selecting roof sheets.

The function of roof sheets extends beyond mere protection. They also contribute to thermal insulation and energy efficiency. A good roof sheet can reflect sunlight and reduce heat buildup in summer. This can lead to lower cooling costs. Yet, not all roofing materials perform equally well in insulation. The choice of material and installation methods can significantly impact overall energy efficiency. Adjustments and improvements may be necessary over time.

Roof sheets play a crucial role in protecting buildings from the elements. There are various types available, each made from different materials. Common options include metal, polycarbonate, and fiberglass. Metal sheets are often favored for their durability. They can withstand harsh weather and resist corrosion. Polycarbonate sheets are lightweight and impact-resistant, making them great for areas needing natural light. Fiberglass offers excellent insulation but may not be as sturdy as metal sheets.

When choosing a roof sheet, consider the climate in your area. Heavy rain or snow might require more robust materials. Tips: Check local regulations about roofing materials. This can save you from future headaches. Also, look for installation guides online. They can help you understand the process better.

Each material has its drawbacks. Metal sheets can be noisy during rain. Polycarbonate may yellow over time. Fiberglass can be prone to cracking under stress. Reflect on what fits your needs best. Consider doing test installations if possible. You wouldn’t want to rush this important decision.

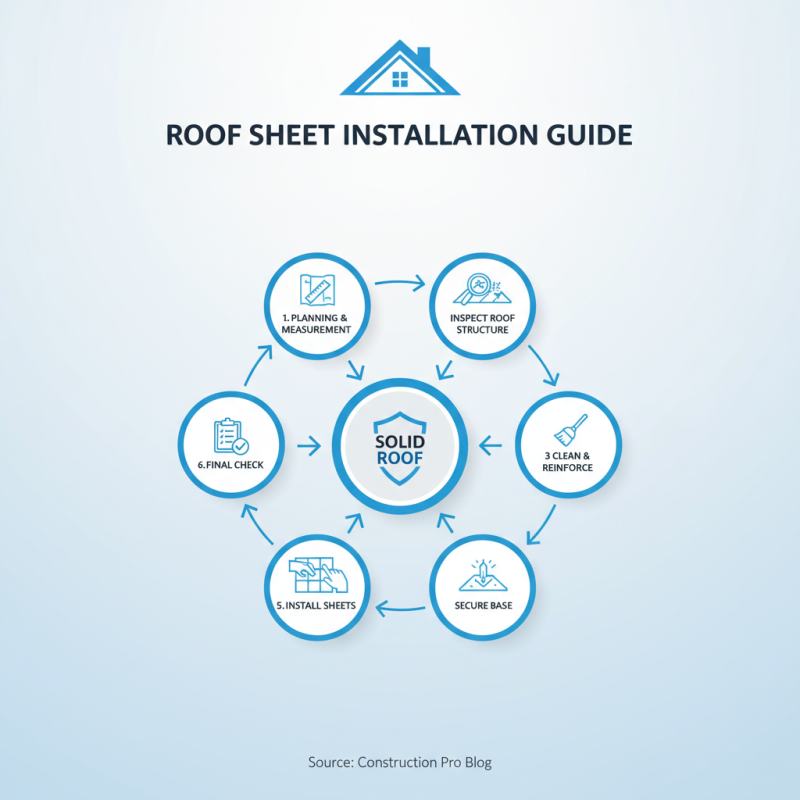

The installation process of roof sheets begins with proper planning. Measurement accuracy is crucial. Evaluate the roof structure carefully. Most experts suggest checking for any damage before starting. The roof must be cleaned and sometimes, reinforced. This ensures a solid base for the sheets.

Choosing the right materials is significant. Many professionals recommend metal or polycarbonate sheets for durability. According to industry statistics, nearly 60% of roofing failures stem from poor installation. Therefore, hiring qualified labor is important. Workers must follow the manufacturer's guidelines closely. Mistakes at this stage can lead to leaks and premature wear.

Once the sheets are in place, securing them correctly is vital. Fasteners should be evenly spaced, usually every 12 to 18 inches. Over-tightening can cause material damage. Additionally, gaps can develop if not spaced properly, leading to future problems. A thorough inspection is needed after installation. This step often gets overlooked, but it is essential for longevity.

Roof sheets play a significant role in construction. They offer several benefits that make them a popular choice among builders. One of the main advantages is their lightweight nature. This feature simplifies the lifting and installation process. Workers can handle the sheets easily, reducing labor costs and time.

Another benefit of roof sheets is their durability. They can withstand harsh weather conditions. From heavy rain to intense sunlight, roof sheets hold up well. This longevity reduces the need for frequent repairs. However, imperfections in installation can lead to leaks. It’s crucial to address potential flaws during setup.

Moreover, roof sheets come in various materials. There are metal, plastic, and fiberglass options available. Each type has its benefits and challenges. For instance, while metal sheets are strong, they can be prone to rust. It’s essential to choose the right material based on local environmental conditions. In some cases, the cost-effectiveness of roof sheets might outweigh their drawbacks. Reflecting on these factors can ensure a solid decision in construction projects.

| Dimension | Description | Benefits |

|---|---|---|

| Material | Common materials include metal, polycarbonate, fiberglass, and asphalt. | Durability and weather resistance. |

| Weight | Weight can vary from lightweight (polycarbonate) to heavy (metal). | Ease of installation and reduced structural support needs. |

| Thickness | Ranges typically from 0.5mm to 2mm. | Better insulation and energy efficiency. |

| Installation | Can be installed on a variety of roof types. | Quick installation can reduce labor costs. |

| Lifespan | Lifespan can range from 10 to 50 years depending on material. | Long-term investment and reduced maintenance costs. |

Maintenance is crucial for the longevity of roof sheets. Regular inspections help catch problems early. Look for rust, cracks, or loose fittings. A small issue can escalate quickly. Clean debris from the surface to prevent water buildup. This simple task reduces wear and tear.

Materials used in roof sheets can affect their durability. Metal sheets may require periodic repainting to prevent corrosion. On the other hand, plastic sheets can become brittle over time. Environmental factors play a big role. UV rays and heavy rain can shorten lifespan.

Consider the installation angle. A steeper pitch can help water runoff, limiting moisture retention. However, tight spaces can make maintenance difficult. Take the time to assess your roof's accessibility. This reflection can lead to better long-term care strategies. Missed maintenance can result in costly repairs. Address minor issues promptly to avoid major problems.