Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving world of construction, "Roof Tiles Manufacture" stands out as a crucial aspect that combines artistry with engineering. As industry expert John Smith, a veteran in the roofing sector, aptly stated, “The quality of roof tiles not only protects homes but also enhances their aesthetic appeal.” This emphasizes the significance of meticulous craftsmanship and innovative techniques in creating roof tiles that meet the demands of both function and design.

Successful roof tile manufacturing requires a deep understanding of materials, production processes, and market trends. With the increasing focus on sustainability and energy efficiency, manufacturers must adopt practices that align with modern environmental standards. By implementing the right strategies, businesses can not only improve their product quality but also expand their market reach, ensuring long-term success in a competitive landscape.

Moreover, mastering the nuances of "Roof Tiles Manufacture" is essential for staying ahead of industry trends. From selecting the appropriate raw materials to employing cutting-edge manufacturing technologies, each step plays a pivotal role in delivering superior roof tiles that meet consumer expectations. By following these ten essential tips, manufacturers can position themselves as leaders in the market, ready to tackle the challenges of today’s roofing industry.

Understanding the basics of roof tile manufacturing processes is crucial for anyone looking to venture into this competitive industry. The manufacturing process typically starts with raw material selection, primarily clay, concrete, or slate. Each material has unique properties that affect the durability, aesthetics, and overall performance of the final product. According to the National Roofing Contractors Association, using high-quality raw materials can increase the lifespan of roof tiles by up to 30 years when properly manufactured, thereby reducing costs for both manufacturers and consumers in the long run.

One essential tip for successful roof tile manufacture is to implement quality control measures at every stage of production. This includes regular testing of raw materials and monitoring the curing times to ensure optimal strength and resilience. A report from the International Tile Producers Association highlights that manufacturers who utilize automated quality checks tend to experience a 20% reduction in defects, which significantly enhances customer satisfaction and reduces warranty claims.

Another important factor is understanding market trends and customer preferences. For instance, the demand for eco-friendly and energy-efficient building materials is on the rise, and manufacturers should consider incorporating sustainable practices in their production. This could include using recycled materials or innovative production techniques that minimize waste. Implementing these insights can not only meet market demand but also improve a manufacturer’s standing in a rapidly evolving industry.

| Tip Number | Tip Title | Description | Importance |

|---|---|---|---|

| 1 | Understand Material Properties | Choose the right materials for durability and aesthetics. | High |

| 2 | Invest in Quality Equipment | Use modern machinery to enhance production efficiency. | High |

| 3 | Establish Quality Control | Implement strict quality checks at every production stage. | Critical |

| 4 | Train Your Workers | Provide comprehensive training for optimal performance. | High |

| 5 | Utilize Efficient Processes | Streamline production processes to reduce waste. | Medium |

| 6 | Adopt Sustainable Practices | Incorporate eco-friendly materials and processes. | Medium |

| 7 | Focus on Research and Development | Invest in R&D for continuous improvement in product quality. | High |

| 8 | Implement Effective Marketing Strategies | Promote your products effectively to reach your target audience. | High |

| 9 | Offer Excellent Customer Support | Provide support pre and post-sale to build customer loyalty. | Critical |

| 10 | Evaluate and Adapt | Regularly assess processes to improve production efficiency. | Medium |

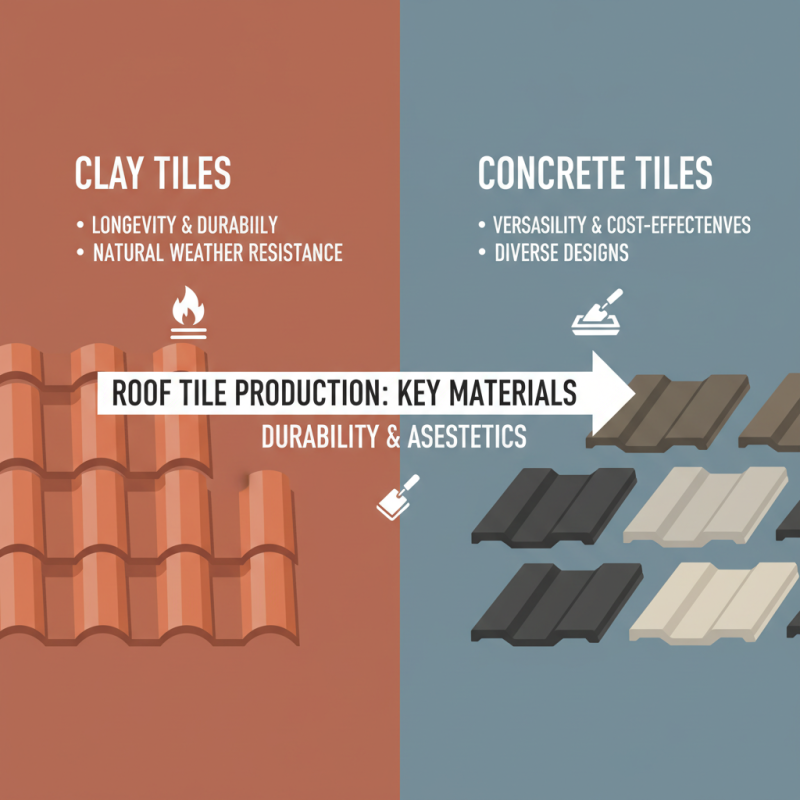

The production of roof tiles requires careful selection of key materials that impact both durability and aesthetic appeal. One of the most commonly used materials is clay, known for its longevity and natural resistance to harsh weather conditions. Clay tiles are typically fired at high temperatures, leading to a hard, robust finish that can withstand various environmental challenges. In addition to clay, concrete is another vital material, offering versatility and cost-effectiveness. Concrete tiles can be molded into various shapes and colors, providing manufacturers with the flexibility to create diverse designs that cater to different architectural styles.

Another important ingredient in roof tile production is natural stone, which lends an exquisite look and exceptional durability. Slate, for instance, provides a unique aesthetic and is highly resistant to fire, making it a popular choice in premium roofing solutions. Furthermore, synthetic materials like polymer and fiberglass are increasingly being used for roof tiles, allowing for lightweight options that still maintain strength and resilience. Understanding the properties and benefits of these materials is crucial for manufacturers aiming to produce high-quality roof tiles that meet consumer demands for performance and visual appeal.

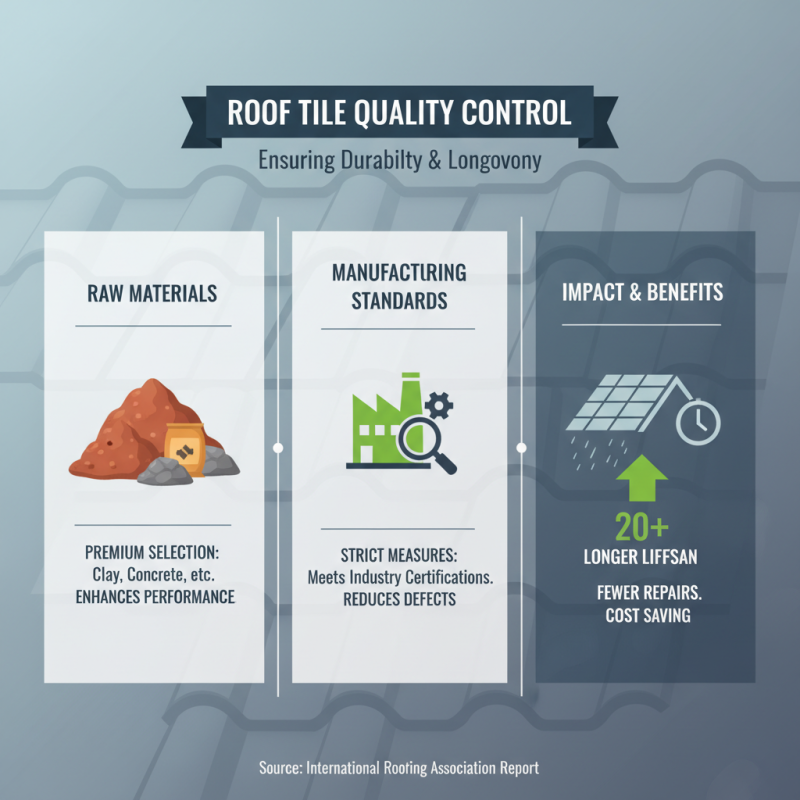

Quality control is a critical aspect of roof tile manufacturing, ensuring that the finished product meets industry standards for durability, aesthetic appeal, and functionality. According to a recent report by the International Roofing Association, manufacturing defects can lead to costly repairs and reduced lifespan of roofing materials, emphasizing the importance of stringent quality measures. One essential quality control measure is the meticulous selection of raw materials. High-quality clay, concrete, or other materials not only enhance the functional performance of roof tiles but also contribute to their longevity, potentially increasing the lifespan by 20% or more compared to inferior materials.

Another crucial aspect of quality control in roof tile manufacturing is the implementation of rigorous testing protocols. Key tests include compressive strength, water absorption, and freeze-thaw resistance, as outlined in standardized guidelines by organizations like ASTM International. For instance, roof tiles that successfully pass compressive strength tests must withstand a minimum load without cracking, as failures in this area can lead to significant structural issues. Regular inspections throughout the production process, combined with these tests, can drastically reduce the rejection rates of finished products and ensure that only those meeting quality standards reach the market, thus enhancing customer satisfaction and protecting brand reputation.

Innovative techniques in roof tile manufacture can significantly enhance durability, ensuring that products withstand environmental stresses over time. One such technique involves the use of advanced material compositions, incorporating additives that improve resistance to extreme weather conditions, UV exposure, and thermal fluctuations. For example, blending traditional materials with synthetic fibers can strengthen tiles, making them less prone to cracking and chipping. This strategic formulation not only extends the lifespan of roof tiles but also contributes to energy efficiency by reflecting heat and reducing the urban heat island effect.

Another important innovative practice is the integration of precision engineering in the manufacturing process. By utilizing state-of-the-art machinery and automated processes, manufacturers can achieve greater consistency and quality in their products. Techniques such as controlled curing and precise temperature regulation during production are essential in creating tiles that resist warping and degradation. Additionally, employing advanced testing methods during the production phase helps to identify any potential weaknesses in the tiles, allowing for necessary adjustments before they reach the market. These innovations not only bolster the durability of roof tiles but also enhance their performance in a competitive landscape.

Sustainability in roof tile manufacturing is increasingly crucial as industries seek to minimize their environmental impact. Implementing eco-friendly materials is a pivotal practice, where manufacturers can choose recycled or locally sourced raw materials to reduce carbon footprints. Moreover, by utilizing natural clays and avoiding toxic additives, manufacturers not only enhance the sustainability of their products but also ensure healthier end-use environments.

Another key aspect of sustainable practices in this sector is energy efficiency. Adopting advanced firing techniques and technologies can significantly lower energy consumption during production. For instance, using regenerative thermal oxidizers reduces waste gas emissions, while innovations like solar energy can power various manufacturing operations. Additionally, integrating water recycling systems can greatly minimize water usage and runoff, further promoting eco-conscious production methods. These practices not only fulfill regulatory requirements but also appeal to increasingly environmentally aware consumers.