0102030405

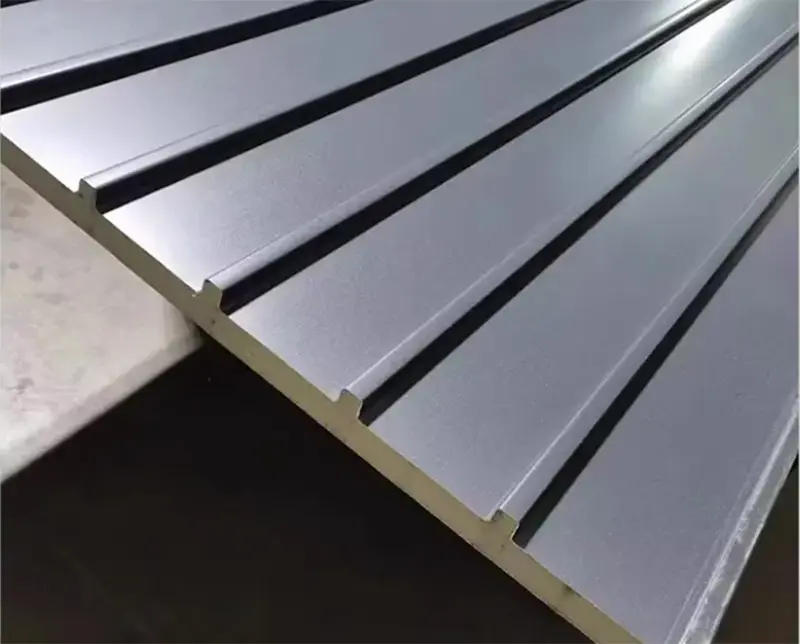

Aluminum filled with Polyurethane Sandwich Panel for roofing heat insulated and moisture protection

description2

Core Material : Aluminum alloy + Polyurethane Foam.

Alumnium alloy : As we all know, its biggest advantage is good corrosion resistance.

Polyurethane foam is the most environmentally friendly thermal insulation material in the world. Under high temperature test, its thermal insulation performance decreases by less than 3% in 25 years.

Compared with traditional materials, it has excellent thermal insulation and cold resistance. It greatly reduces heating and cooling energy consumption, thereby saving energy expenditure and is cost-effective.

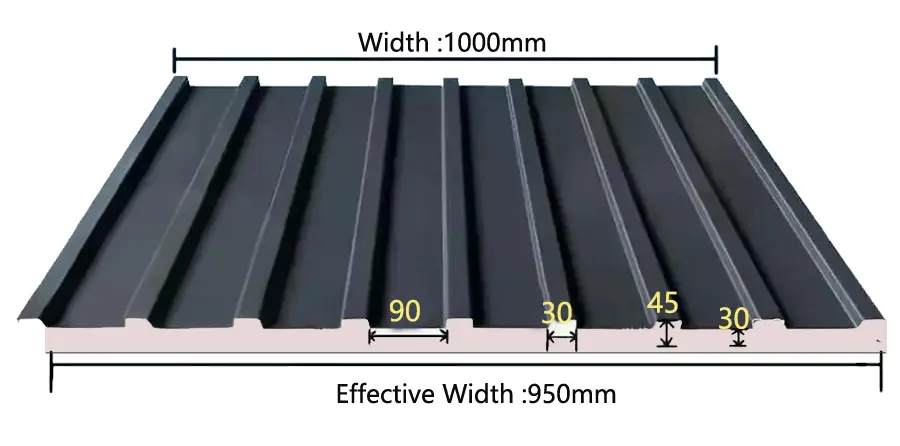

| Core material density | pu about 38-40 kg/m³;pir : 40-42 kg/m³ |

| Core material thickness | 30mm-45mm |

| Aluminum alloy thickness | 0.4mm ,0.5mm ,0.7mm |

| Effective Width | 950mm |

| Thermal Conductive | <0.023 |

| Fireproof Level | A |

| Temperature tolerable | -55° - 160° |

Aluminum - alloy polyurethane roof tiles have the following advantages:

Durability

- They have excellent weather resistance. The polyurethane coating can effectively prevent damage from ultraviolet rays, rain, snow, and other harsh weather conditions, and is not easy to fade or corrode.

- The combination of aluminum alloy and polyurethane endows the roof tile with good impact resistance and abrasion resistance, which can withstand the impact of hail and other objects and has a long service life.

Thermal Insulation

- The polyurethane material has good thermal insulation properties. It can help keep the indoor temperature stable, reducing energy consumption for heating in winter and cooling in summer, and thus achieving certain energy - saving effects.

Lightweight

- The aluminum alloy structure makes the roof tile relatively lightweight. This is beneficial for the roof structure, reducing the load - bearing requirements of the building and making installation more convenient.

Aesthetics

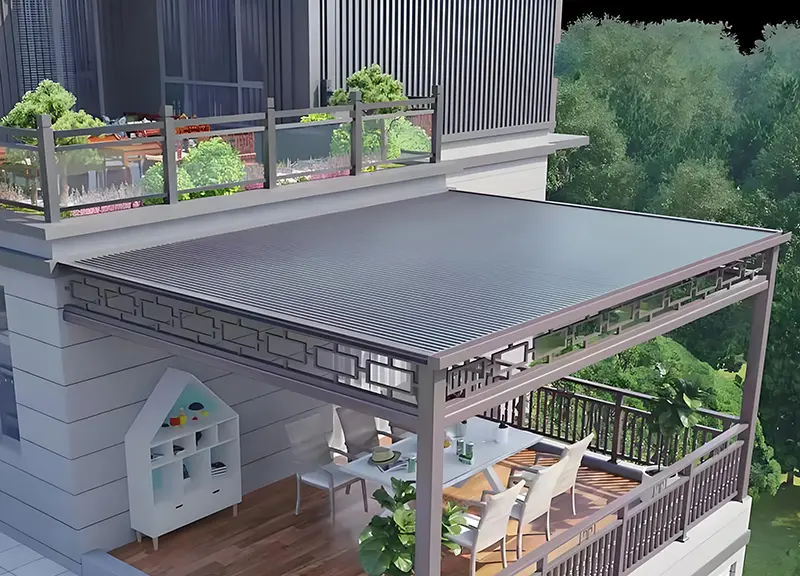

- They usually have a beautiful appearance, with a variety of colors and textures available. They can enhance the overall aesthetic of the building's exterior and are suitable for different architectural styles.

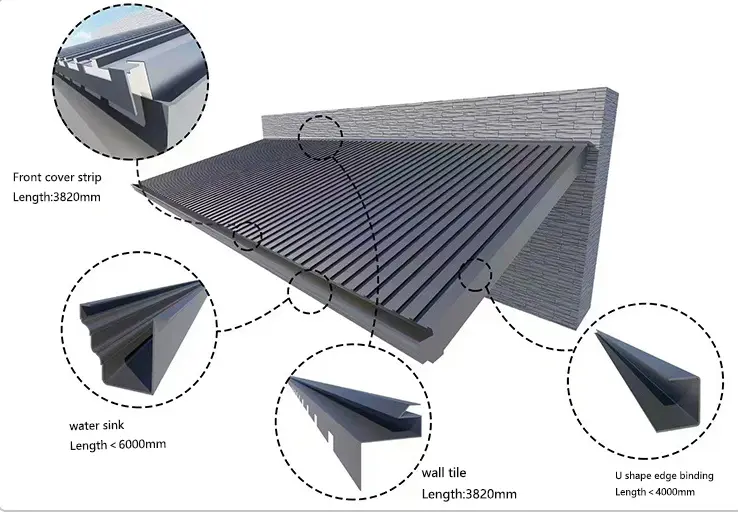

Accessories

1. Preparation before installation

Make sure the installation surface is flat, clean, and free of debris and dust.

Prepare the required installation tools and materials, such as screws, self-tapping screws, clip-on sealing covers, wrenches, etc.

2. Installation steps

* Fix the sink: First, place the sink in the predetermined position and fix it with screws.

* Install the side trim strips: According to the actual situation of the roof, fix the side trim strips to ensure the stability and aesthetics of the tile during installation.

* Lay the first board: Place the first Great Wall insulation tile on the starting strip (if installed) and fix it in the groove with self-tapping screws. Make sure the screws are firmly fixed, but avoid over-tightening to damage the tile.

* Snap-on splicing: Next, snap the subsequent tiles onto the tail of the previous tile in turn and fix them with self-tapping screws. Repeat this step until all tiles are laid.

* Install the sealing cap: After all tiles are laid, use the improved and upgraded clip-on sealing cap to seal the edges of the tiles. The sealing cap can be fixed with screws or glue to ensure stability and prevent it from falling off.

3. Precautions

During the installation process, make sure that each tile fits tightly to avoid gaps that cause water leakage.

When using screws to fix, pay attention to moderate force to avoid damaging the tiles or the installation surface.

After the installation is completed, it is recommended to check and test to ensure that the tiles are firmly installed and have good waterproof performance.

Project

Packing

LCL Packing

- Inner layer: generally plastic film or bubble film is used, which can play a moisture-proof and buffering role, prevent the surface of the aluminum alloy tile from being scratched and worn during transportation and storage, and can also resist certain water vapor erosion.

- Middle layer: corrugated cardboard or foam board is used to further buffer and reduce shock, protecting the aluminum alloy tile from collision and impact.

- Outer layer: Use sturdy wooden boxes or fiberboard boxes tied with steel belts to enhance the overall compression resistance and fall resistance, ensuring safety during handling, loading and unloading and transportation.

Full Container : Use corrugated cardboard or foam board protect the surface.

Negotiable.