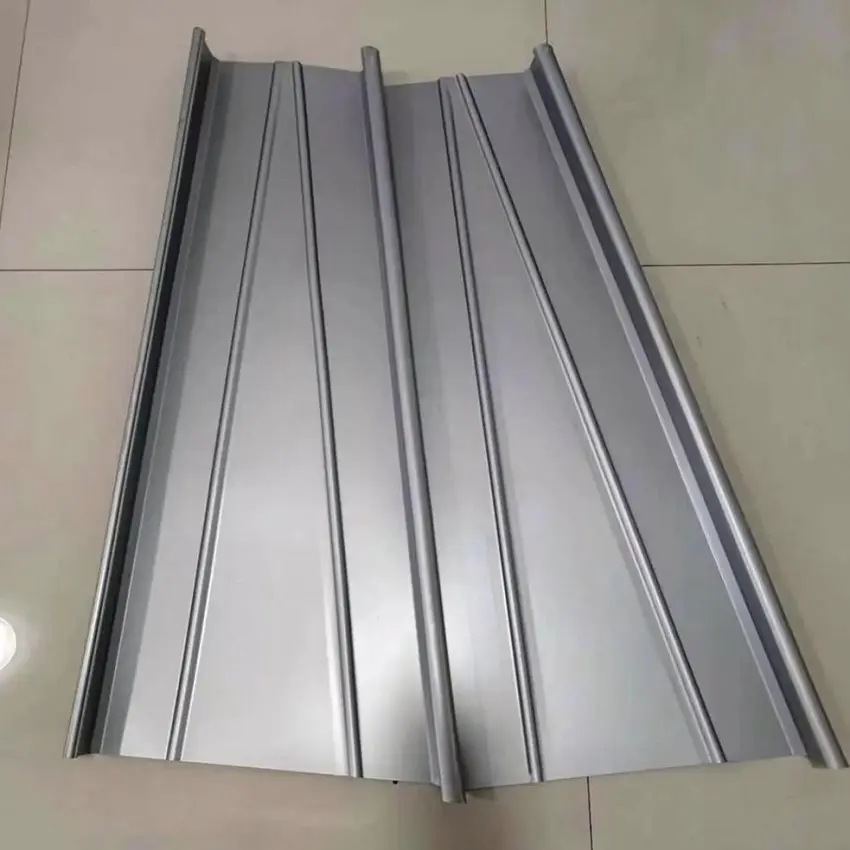

3003/3004 Aluminum magnesium and manganese 65-430 standing seam metal roof sheet

Specification

|

Name |

standing seam roof tiles |

|

Material |

3003 Aluminum alloy |

|

Application |

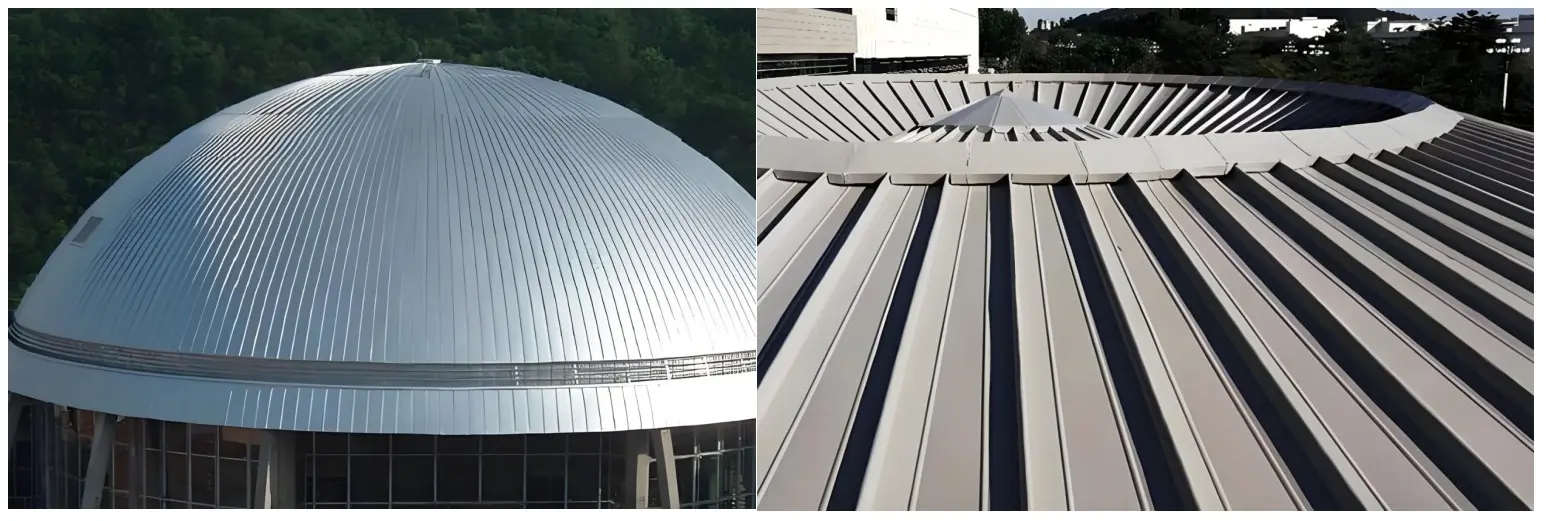

Artistic roof, Long span roofing |

|

Service life |

50+ years |

|

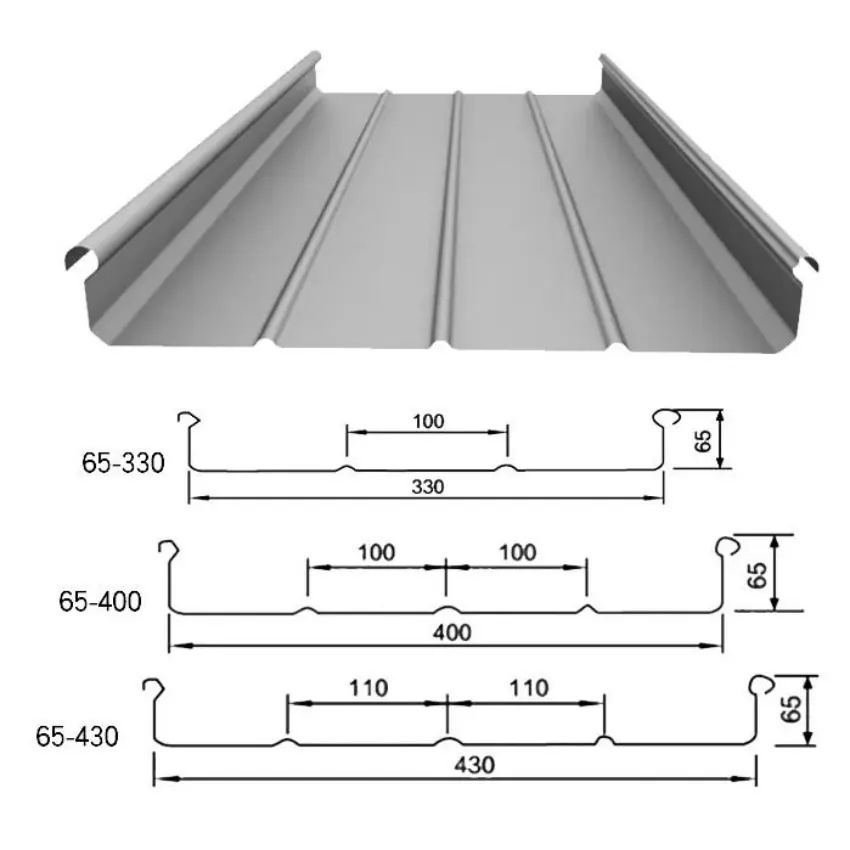

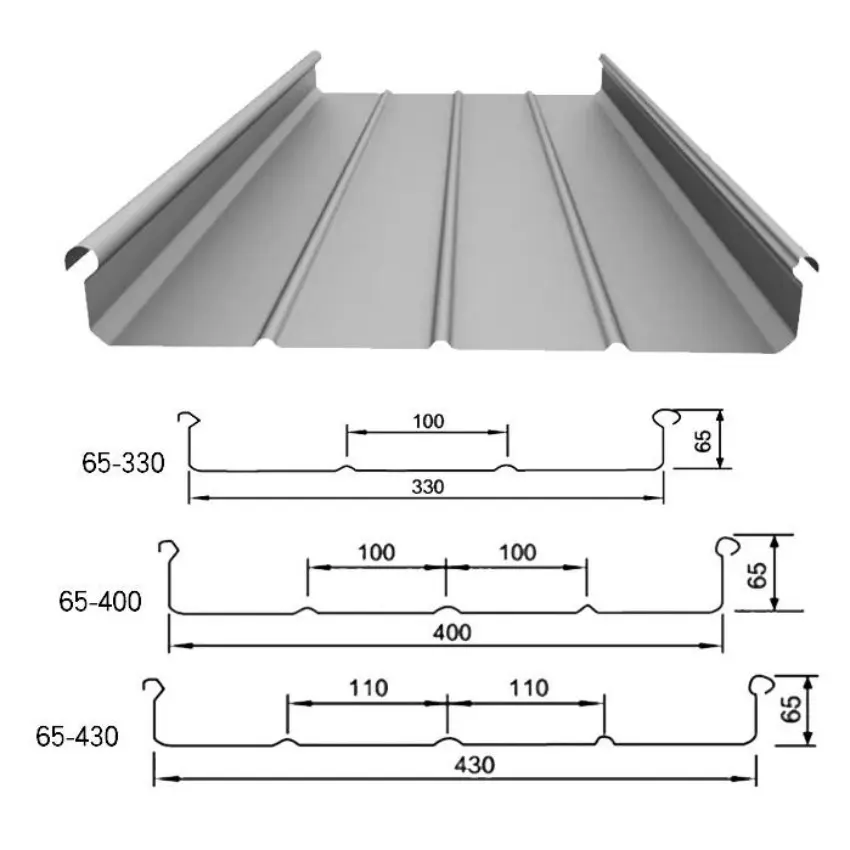

Dimention |

Width-400mm/430mm,Height-65mm; |

|

Thickness |

0.7mm-1.2mm |

|

Weight |

2.37g/cm³ |

|

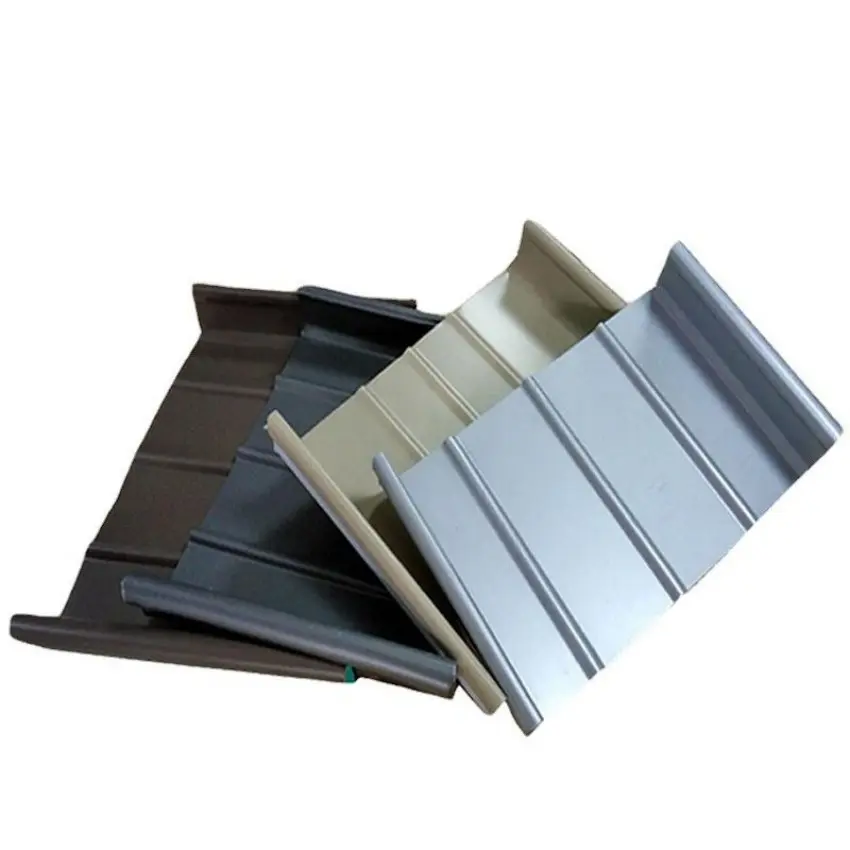

Color |

Usual color-Grey, Accept custom |

|

Surface |

Fluorocarbon paint |

|

Warranty |

30 years |

|

Advantage |

Super Corrosion resistance;long lasting color;Easy install,Etc |

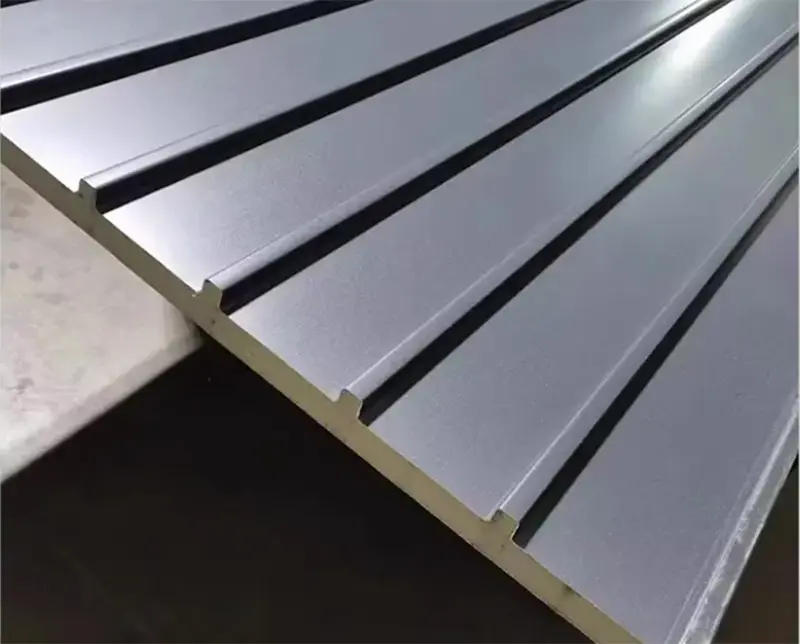

PRODUCT DESCRIPTION

Expanded width: 600mm

Length :Customize

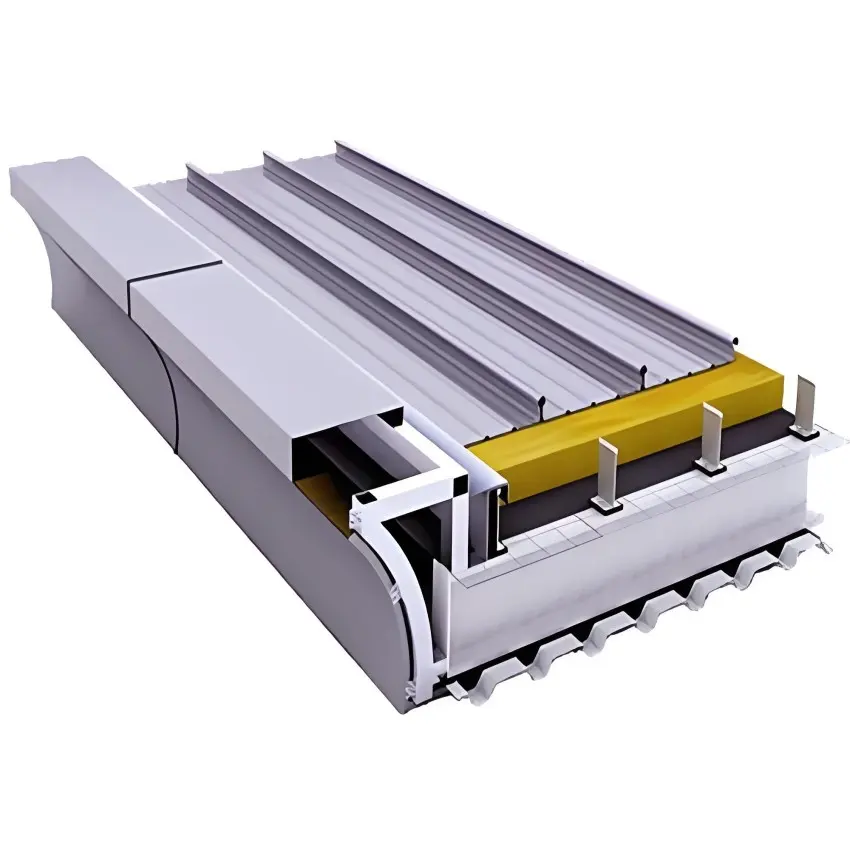

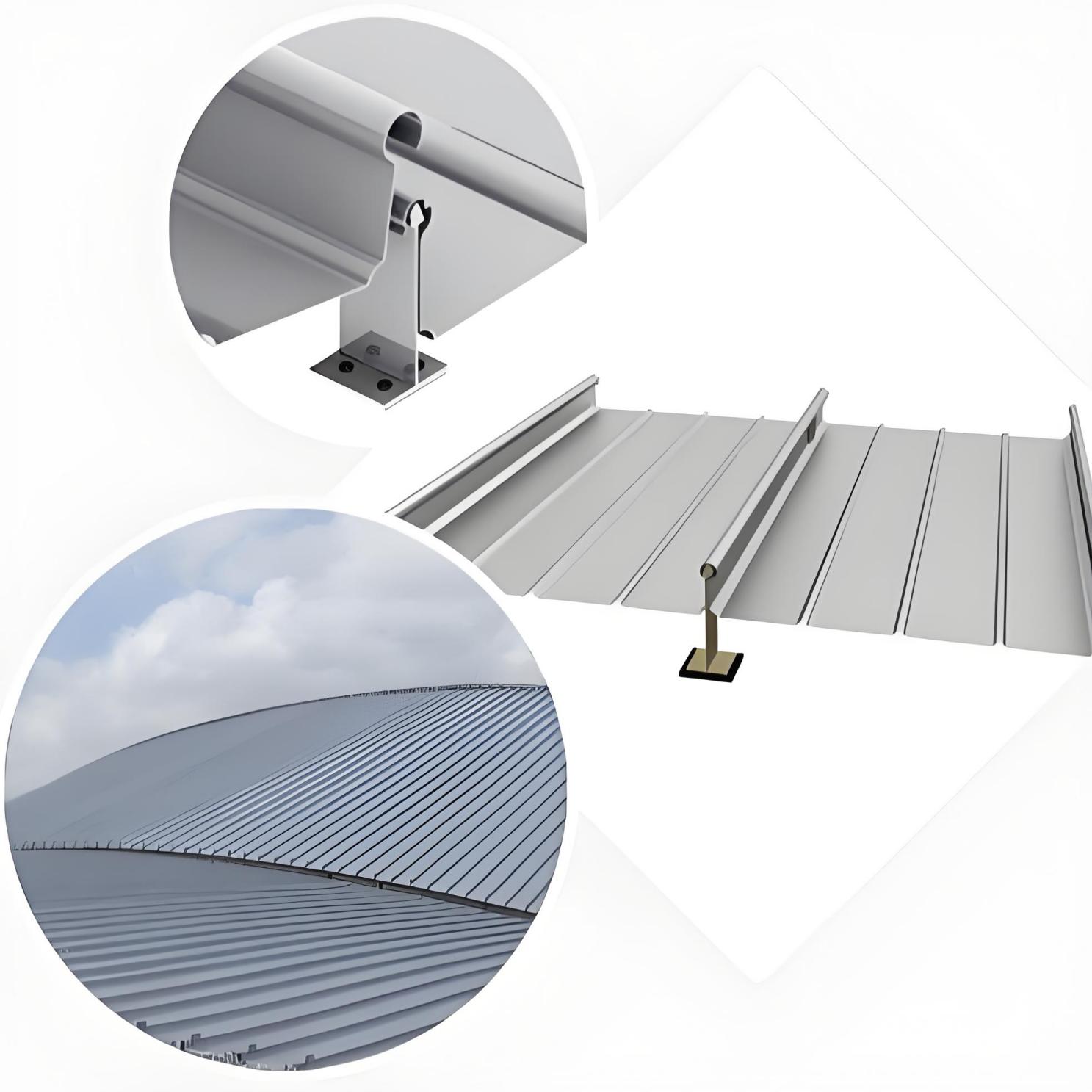

The vertical lock edge system is a traditional aluminum-magnesium-manganese plate installation system. By using professional vertical edge and bite equipment, the vertical edges of two plates are bitten along the length of the strip, so as to connect the roof or wall into a whole. The system does not require gluing and is 100% structurally waterproof. This system can save a lot of installation time, especially for large roofs or walls, providing an effective way to reduce costs. In addition, the vertical lock seam system is also very suitable for harsh climate environments, such as places with strong winds, heavy rain and snow. The vertical lock seam system has a vertical edge height of 65mm, giving the building a rhythmic and modern appearance.

ADVANTAGES & CLASSIFICATION

Aluminum-magnesium-manganese alloy plate metal aluminum plate is divided into 10 series, among which the aluminum used for construction is mainly 3000 series, such as AA3003, AA3004, AA3005, aluminum-magnesium-manganese roofing material aluminum surface treatment includes: natural color unpainted products and painted products:

Non-painted products: hammered aluminum alloy plate (irregular pattern), embossed plate (formed with regular pattern by mechanical embossing); pre-passivated alumina surface treated plate. This type of product does not have paint treatment on the surface of the plate, does not have high requirements for the surface appearance, and has a lower price.

Paint products: According to the coating process, they are divided into: spray plate products and pre-roller coated plates;

According to the type of paint, they can be divided into: polyester, polyurethane, polyamide, modified silicone, epoxy resin, fluorocarbon, etc.

To extend the paint's resistance to aging under the action of sunlight and ultraviolet rays as much as possible, among which PVDF paint (fluorocarbon coating) has the best anti-aging performance. It is the strongest organic synthetic compound known to mankind for its UV resistance. Fluorocarbon coated aluminum plates, according to different quality requirements, use horizontal automated two-coat-two-bake, three-coat-three-bake and four-coat-four-bake roller coating processes. The pre-coated PVDF coating has a resin content of 70%-80%. It is roller-coated on a high-speed continuous unit through chemical pretreatment, initial coating, fine coating and other processes. The front coating is generally 25μm, and the back is coated with anti-corrosion paint.

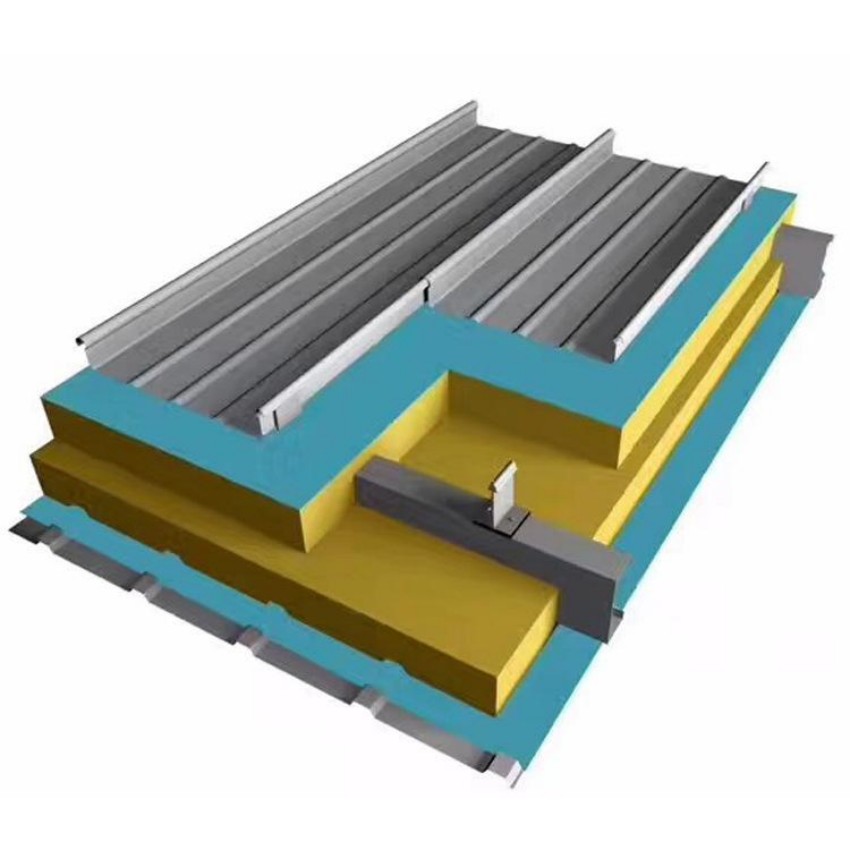

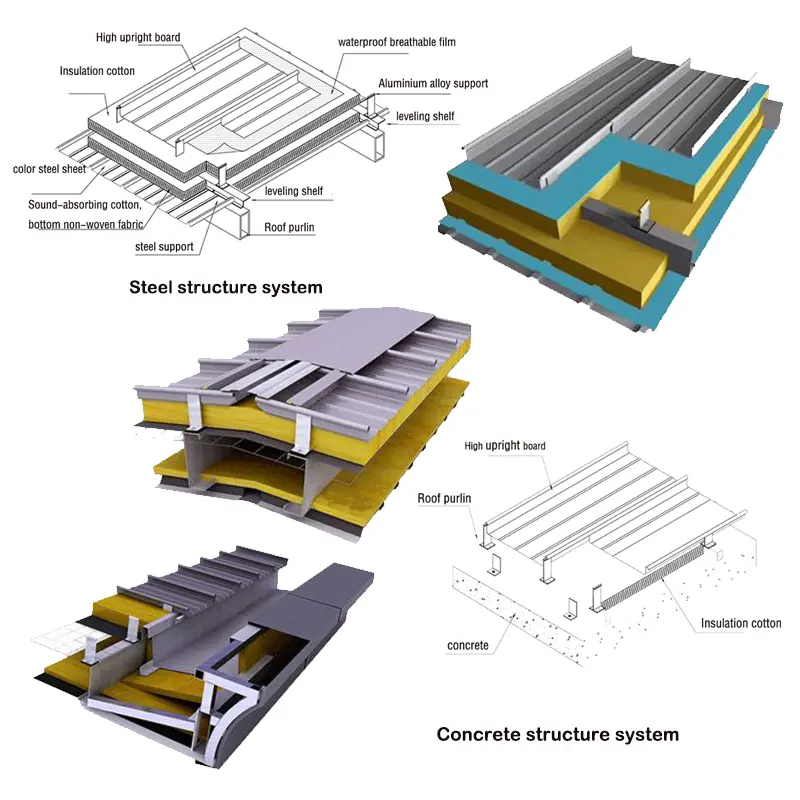

USUAL STRUCTURE

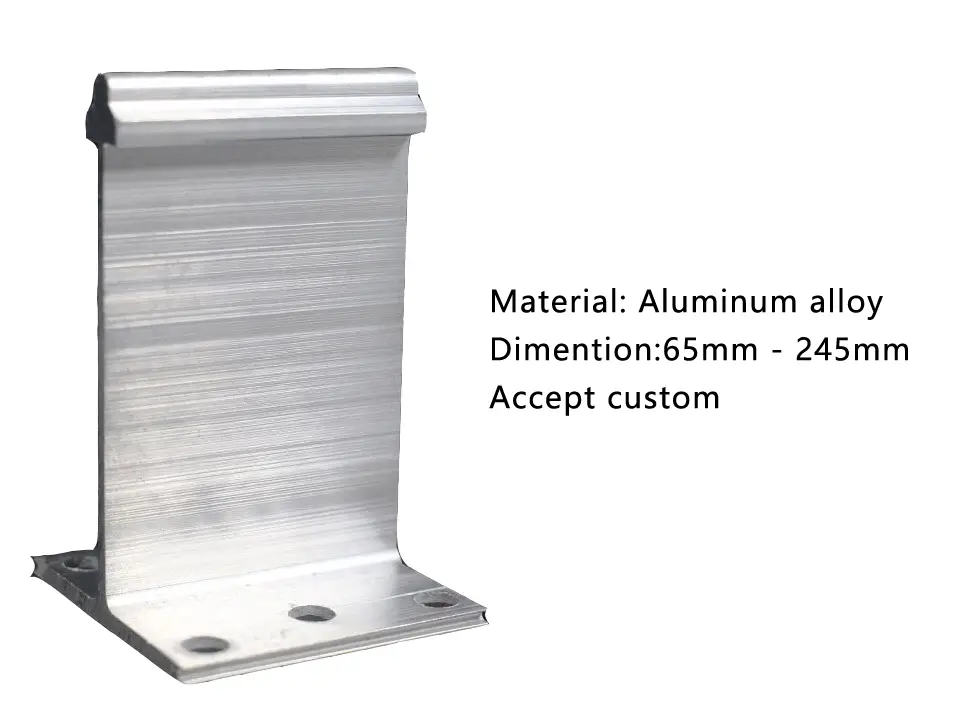

FIXED KITS

PROJECT CASE

PACKING